Introduction

This blog details retesting the drill press controllers' DC-DC power supply, fitting components related to the outputs and testing the output drivers.

Retesting the Power Supply

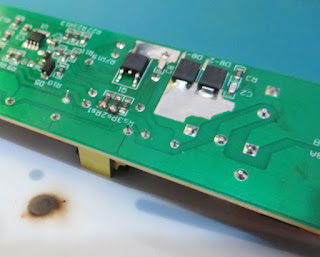

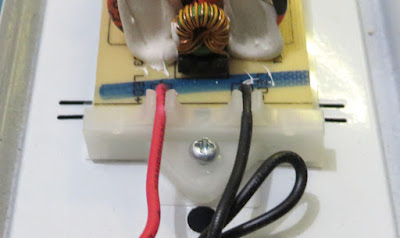

The original inductor fitted to the PCB (Printed Circuit Board) was removed and replaced with a 10 μH inductor. Testing the supply with the same load as the last post, the regulation at 165 mA and 330 mA was better than 0.1 %. The unloaded voltage was measured at 3.36 V, which is within component tolerances.

A short regulation test was made on the output of the AC-DC bricks after fitting the necessary parts to the PCB. The bricks output was as expected in tolerance.

|

| PCB Setup for Power Supply Testing |

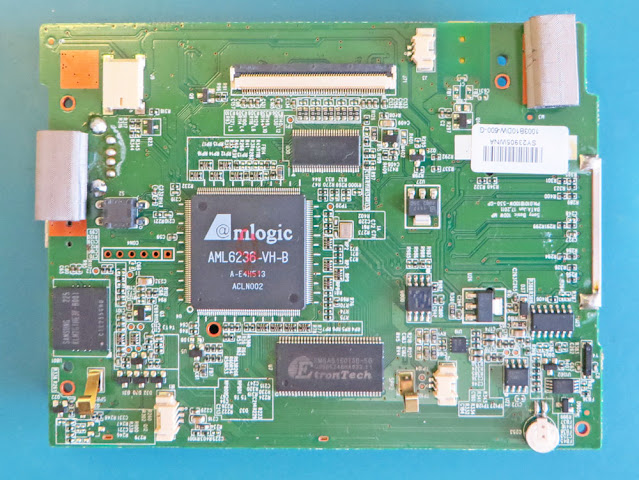

Fitting Output Connected Microcontroller

The microcontroller and associated output hardware were fitted to the PCB, after which tests were performed. For the relay outputs, the output driver VND5160J was fitted to the PCB and then load tested. Separate FDN337N devices control the emergency stop and status LEDs, which were also checked.

Solid State Relay (SSR) Outputs

Following the fitting of the microcontroller and the output driver for the SSR, an external AC supply, SSR, and mains lamp were connected.

Instead of the previously mentioned SSR from TE, part SSRD-240D25A, a Multicomp MPKSI240D10-L(070) was selected. The control voltage for the Multicomp part is between DC 4 – 32 V, meaning an installation can be configured with one or two SSR devices. The clip below shows a lamp connected through the SSR powered by a transformer. The PSoC was programmed to toggle the SSR control input.

For reference, the output of the SSR was captured on an oscilloscope.

|

| SSR Output |

Status and Emergency Stop LEDs

The EAO illuminated pushbutton featured in the original drill press design was listed as superseded and replaced with the EAO part 84-5241.2B20. The original code was updated to flash the status LED, indicating the code was operating. No changes were needed for the Emergency Stop LED. In the clip below, both LEDs are shown operating.

In the next post, the input circuitry will be fitted and tested.