Prompting this blog was my dismay which was caused during a recent scrounge through some component draws for a humble load resistor. The culprit is shown below, just an innocuous resistor right!

Before using the resistor a standard multimeter check was performed. This measurement indicated that the resistance was unexpected high resistance. After pulling lightly on the two legs of the resistor simultaneously the reason for the high resistance was apparent, mechanical failure. This faulty resistor would have been moved around in a draw of spare parts for the better part of ten years before it was used, possibly adding to its demise.

| Old resistor |

| Old faulty resistor |

Whether mechanical failure of the resistor occurred during manufacturing or more likely as a result of being mistreated during storage, this highlighted the limited shelf life for salvaged or even new electronic parts. Certainly some electronic parts are more susceptible to the rigors of handling, storage damage and part aging.

Salvaging Parts

This blog and subsequent blogs on the same subject, intend on showing some of the parts than can be salvaged from electronic equipment and possible issues that can be experienced with these parts. Whilst not all factors that damage electronic parts has been accounted for, the factors mentioned should serve as a guideline for those performing salvaging themselves.

A fully functioning control board from a NESS security system (D8X D16X) will serve as the example. For any board being salvaged a check with a multimeter can save the hassle of removing an already faulty component.

Line Out

For the telephone interface, shown by the yellow box, are parts such as optocouplers, a relay and an LMV324 rail to rail op amp. All these parts can be readily used in new projects.

Input Section

The input section has not been particularly noted for parts to salvage although the MELF and larger surface mount resistors come in useful for higher voltage designs. Of interest in this section is the PCB design itself and use or lack of components. More on spark gaps in a following blog.

Sections Not Noted

In the remaining sections are more logic level FET's BUK9245, ULN2803 driver and connectors would also come in useful when designing.

Salvaging Equipment

The tools required for removing salvaged electronics will vary depending on the equipment and budget. For most types of salvage work equipment such as needle nose pliers, SMT tweezers, a second gas or mains powered soldering iron and a range of drivers for different types of screws and bolts. On occasion equipment designers use TORX or HEX bolts to secure equipment.

As an example a computer power supply, which is commonly a single side circuit board, can be stripped of electronics using a soldering iron and a solder sucker or wick.

For circuit boards with tracks on both sides, with plated thru holes, desoldering can use more consumables such as solder wick especially for parts with multiple legs.

Surface mount components can be removed using additional equipment such as a soldering station with tweezers or a reflow oven can reduce issues relating to mechanical stress on electronic parts or over-heating when compared to using traditional solder wick. For the higher end user a hand held air convection tool offers timed temperature control however it is usually out of the price range for most hobbyists.

One noteworthy item not commented enough in other blogs for my liking, is the use of Personal Protective Equipment (PPE) when handling equipment made with lead based solder. This should not be taken as an alarmist comment although viewed as a simple measure to limit ones exposure to lead during the salvaging process.

Workpiece Holding

When small to medium sized circuit boards, up to 150mm in width, are worked on for salvaging, a circuit board holder of any variety assists when changing between the component and solder sides of the board.

For the salvaging process with the Ness control board a PCB holder from Altronics, T2356 shown above, was used.

Salvaging Components

To begin with the two and three pin components, with thru-hole (TH) leads, will be removed from the NESS board. As mentioned above these components consist of capacitors, varistors and regulators.

Relay- Thru Hole

A through hole relay, which usually has 6 or more leads, can be removed with the old favourite desolder braid or a solder sucker.

Surface Mount Components

Removing a surface mount component can pose its own difficulties. Some components can be glued, part of the reflow soldering process, or held to the board with Silastic for mechanical stability. In these instances removal of the component may require some more inventive solutions.

Capacitor - Surface Mount

For removal of a surface mount capacitor the soldering iron tip can usually be applied directly to the exposed pad of the capacitor to melt the solder and the component leg lifted away from the circuit board pad.

Opto-Coupler - Surface Mount

For removal of a surface mount opto-coupler the soldering iron tip can used to heat the two circuit board pads located on one side of the component. There is usually more solder on the opto-coupler pads than components such as resistors and capacitors so additional solder should not be required.

Salvaging Parts

This blog and subsequent blogs on the same subject, intend on showing some of the parts than can be salvaged from electronic equipment and possible issues that can be experienced with these parts. Whilst not all factors that damage electronic parts has been accounted for, the factors mentioned should serve as a guideline for those performing salvaging themselves.

A fully functioning control board from a NESS security system (D8X D16X) will serve as the example. For any board being salvaged a check with a multimeter can save the hassle of removing an already faulty component.

| Ness alarm control board |

The NESS control board has had the heatsink situated within the blue box shown above, however this was removed for visibility of surrounding components. In fact this heatsink would be considered the first salvaged part!

Power Supply

Within the bounds of the blue box shown in the image, are parts associated with a linear power supply. Parts to be salvaged could include the red varistors (V56ZA05P), DIP bridge rectifier, large electrolytic, linear regulator and associated surface mount capacitors.

Microcontroller

The red box identifies the alarm panel processor and another smaller power supply. Due to the age of the alarm panel board the processor, a Cypress Semiconductor MB89F538, this part is listed a obsolete which may preclude it being removed. The remaining crystal, fuse, DIP8 regulator, surface mount capacitors and logic level FET - BUK9245 could all be removed.

Line Out

For the telephone interface, shown by the yellow box, are parts such as optocouplers, a relay and an LMV324 rail to rail op amp. All these parts can be readily used in new projects.

Input Section

The input section has not been particularly noted for parts to salvage although the MELF and larger surface mount resistors come in useful for higher voltage designs. Of interest in this section is the PCB design itself and use or lack of components. More on spark gaps in a following blog.

Sections Not Noted

In the remaining sections are more logic level FET's BUK9245, ULN2803 driver and connectors would also come in useful when designing.

Salvaging Equipment

The tools required for removing salvaged electronics will vary depending on the equipment and budget. For most types of salvage work equipment such as needle nose pliers, SMT tweezers, a second gas or mains powered soldering iron and a range of drivers for different types of screws and bolts. On occasion equipment designers use TORX or HEX bolts to secure equipment.

As an example a computer power supply, which is commonly a single side circuit board, can be stripped of electronics using a soldering iron and a solder sucker or wick.

For circuit boards with tracks on both sides, with plated thru holes, desoldering can use more consumables such as solder wick especially for parts with multiple legs.

Surface mount components can be removed using additional equipment such as a soldering station with tweezers or a reflow oven can reduce issues relating to mechanical stress on electronic parts or over-heating when compared to using traditional solder wick. For the higher end user a hand held air convection tool offers timed temperature control however it is usually out of the price range for most hobbyists.

One noteworthy item not commented enough in other blogs for my liking, is the use of Personal Protective Equipment (PPE) when handling equipment made with lead based solder. This should not be taken as an alarmist comment although viewed as a simple measure to limit ones exposure to lead during the salvaging process.

|

| Ansell cotton gloves |

Workpiece Holding

When small to medium sized circuit boards, up to 150mm in width, are worked on for salvaging, a circuit board holder of any variety assists when changing between the component and solder sides of the board.

|

| Circuit board holder |

For the salvaging process with the Ness control board a PCB holder from Altronics, T2356 shown above, was used.

Salvaging Components

To begin with the two and three pin components, with thru-hole (TH) leads, will be removed from the NESS board. As mentioned above these components consist of capacitors, varistors and regulators.

| Flooding capacitor pins |

Capacitor - Thru Hole

In order to transfer more heat from the soldering iron to the pad on the circuit board, adding a small amount of solder to the pads, of the part being removed, usually helps. The component can then be pulled and rocked out of its original position.

In order to transfer more heat from the soldering iron to the pad on the circuit board, adding a small amount of solder to the pads, of the part being removed, usually helps. The component can then be pulled and rocked out of its original position.

Excessive pulling force applied to the leads of the capacitor whilst desoldering may lead to the pins being partly lifted from the capacitor body. When a visible change is lead length can be seen, then the part should be discarded. Overheating a leaded capacitor is possible although unlikely in most instances. Many leaded capacitors have the maximum working temperature listed on the capacitor.

Regulator - Thru Hole

A similar method to the capacitor removal can also be applied to three terminal regulators such as the 78xx series.

As with the capacitor, it should be noted than one or more of the regulator pins may be connected to large PCB tracks, fills or entire planes on the circuit board. These larger areas of copper require more heating to melt the solder, so flooding the pins with some extra solder can facilitate a better transfer of heat from the soldering iron.

Post removal the regulator, and similarly any other removed parts, would benefit with clean-up to remove the excess solder from the pins. A 78xx series leaded regulator from ST has a storage temperature of 150C, damaging these robust parts is also difficult.Regulator - Thru Hole

A similar method to the capacitor removal can also be applied to three terminal regulators such as the 78xx series.

| Flooding regulator pins |

| Regulator removed |

Relay- Thru Hole

A through hole relay, which usually has 6 or more leads, can be removed with the old favourite desolder braid or a solder sucker.

| Desoldering through hole relay |

While using desolder braid to remove any electronic component, a fan or fume extractor is strongly recommended. Well known brand Weller has an article "Health Hazards From Inhaling and Exposure To Soldering Fumes" describing the risks of inhaling fumes created as a result of desoldering with braid.

| Desoldered relay |

One benefit of using the desolder braid is that during the process of desoldering, while the solder is being wicked from the solder joint, the position of the soldering iron tip can be moved around the component pin. This allows for cleanly desoldered pin and prevents the pin from sticking to the wall of the pad.

Surface Mount Components

Removing a surface mount component can pose its own difficulties. Some components can be glued, part of the reflow soldering process, or held to the board with Silastic for mechanical stability. In these instances removal of the component may require some more inventive solutions.

Capacitor - Surface Mount

For removal of a surface mount capacitor the soldering iron tip can usually be applied directly to the exposed pad of the capacitor to melt the solder and the component leg lifted away from the circuit board pad.

| Surface mount capacitor |

To remove smaller capacitors, each of the exposed legs may need to be heated more than once and the part rocked free. This method is recommended because beneath the capacitor is a plastic former which holds the component flush with the circuit board. This plastic former can be melted if the soldering iron is kept on the component leg for several seconds.

| Removed surface mount capacitor |

For removal of a surface mount opto-coupler the soldering iron tip can used to heat the two circuit board pads located on one side of the component. There is usually more solder on the opto-coupler pads than components such as resistors and capacitors so additional solder should not be required.

| Opto-coupler tweezer removal |

A tip for removing these types of devices is to insert the arms of some stainless tweezers beneath the component. When the two pads on the same side of the device are heated, only a small amount of force is needed to lift the component from the circuit board.

| Opto-coupler removed |

The same technique is applied to the remaining fixed side of the component. Using the tweezers also allows removal of the heated component without the need to touch it directly.

MOSFET - Surface Mount

The last part to removed in this blog is a MOSFET in a DPAK case type. As with the opto-coupler using tweezers can be helpful to lift the component legs.

With no additional solder and the soldering iron applied to the leg of the MOSFET, only a small amount of force is needed to lift each component leg from the circuit board using the tweezers. It may also pay at this stage of the removal to use desolder wick to ensure that the legs of the MOSFET are in no way connected to the circuit board.

To heat the soldered tab of the MOSFET, adding some solder to the tab joint aids in heating the surface mount pad and MOSFET itself.

MOSFET - Surface Mount

The last part to removed in this blog is a MOSFET in a DPAK case type. As with the opto-coupler using tweezers can be helpful to lift the component legs.

| Desoldering leg of MOSFET |

To heat the soldered tab of the MOSFET, adding some solder to the tab joint aids in heating the surface mount pad and MOSFET itself.

| Heating MOSFET tab |

Heating the device and the pad may take several seconds. When the solder near the tab begins to melt, applying horizontal force to the component usually allows the part to be slid off the pad. Heating the tab of the MOSFET for an extended time should be avoided.

| Desoldered MOSFET |

The maximum time a component should be heated can be based partly on the soldering process reflow curve. This curve is not always available from manufacturer data sheets especially for discrete devices so the peak temperature could also be used.

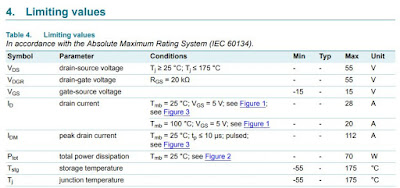

For the MOSFET that was removed from the NESS circuit board, BUK9245-55A, the device is several years old and the MOSFET 'storage temperature' of 175 degrees the only details listed.

|

| BUK9245-55A Characteristics |

As a general rule of thumb the solder reflow peak temperature should not be exceeded for more than 30 seconds. Applying this to the MOSFET removal, with a 260 degree soldering iron set temperature, then it should be safe to use 15 seconds of heating on such a device.

Finally as with any component it should be tested thoroughly before entering the confines of any spare part storage system!