Summary

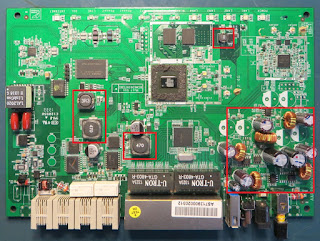

This post details which circuit board components could be salvaged from a Billion BiPAC 7800VDOX Wireless Router.

Router Disassembly

To separate the Wireless Router's grey lid from its base, four rubber feet located on the base of the router enclosure were removed. The removed feet expose the screws retaining the lid.

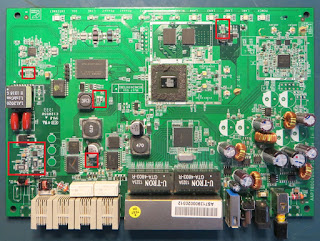

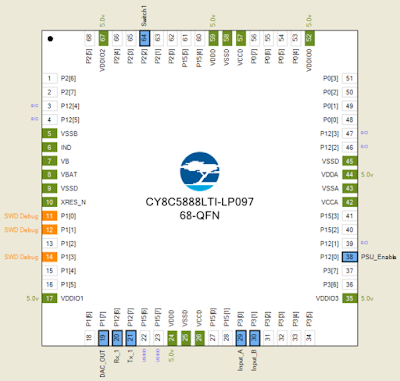

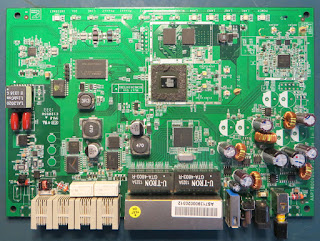

The above image shows the Wireless Router internal Printed Circuit Board (PCB) with the light pipe and rear panel removed.

Parts to Salvage

Cabling

There are two antennas in the lid with RF connectors (RSP / AMC style) which could be salvaged.

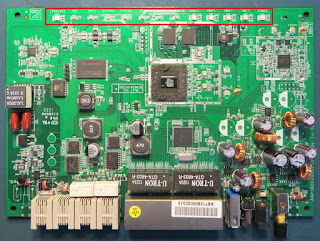

Heat Spreaders

On the PCB are several ceramic heat spreaders (heatsinks) attached to various Broadcom components. These are held down with double-sided tape.

| Mounted Heat Spreaders |

Removing the heat spreaders can be achieved using a tool such as a wide flat blade screwdriver to lever the heat spreaders off carefully.

|

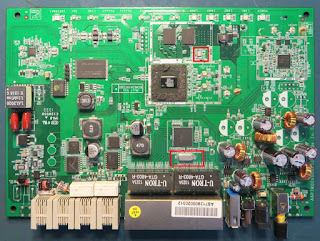

| 7800VDOX Wireless Router PCB with No Heat Spreaders |

Removing the heat spreaders exposes the Broadcom chipsets comprising of the processor, RF and communication hardware. The Broadcom hardware is not suitable for salvage, possibly repair to a similar router.

Inductors

There are open core leaded and PCB mount inductors which could be recycled for other designs.

Diodes

Identified in the image below are single and dual colour surface-mount LEDs.

Oscillators

A 25 MHz thru-hole Crystal is located next to the Broadcom chip responsible for the Ethernet clock and a second surface mount Crystal oscillator can be found by the Broadcom processor.

Relays

The two Fujitsu FTR-C1CA003G miniature relays have a coil operating voltage of 3 V DC with DPDT 1A contacts. These thru-hole relays are worth removing.

Resistors

Distributed across the top and bottom side of the PCB are resistors with case sizes larger than 0805 which can be repurposed. Most are standard resistor values.

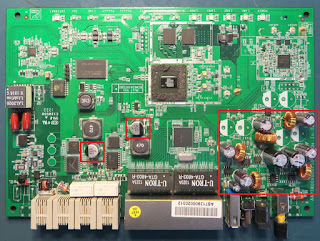

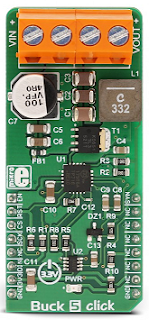

DC-DC Regulators

A mixture of Fitipower DC-DC Step Down Switch mode chips (FR98860 and FR9888) could be removed.

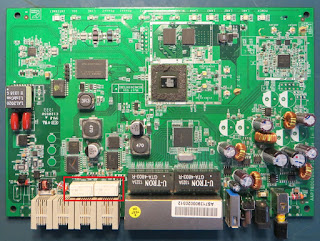

Connectors

The vertical USB connector and DC jack could be removed and reused in another design. Removing and reusing the right-angle Ethernet or RJ connectors should be achievable.

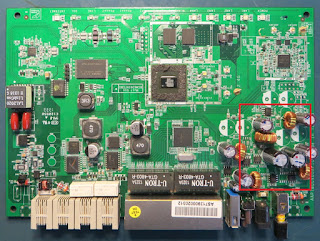

Capacitors

Any of the radial Electrolytic capacitors could be reused. It should be noted that the Su'scon capacitors (SD and SK series) although rated with a useful operating temperature of 105°C (max), have a 2000 hour operating life at the maximum rated temperature. Consider that the Wireless Router may have been operating for 10 years continuously which may have significantly reduced the lifetime of the capacitor.

The other surface-mount Electrolytic capacitors (22uF) appear to be the Panasonic FK series which are rated to 105°C with a 2000 hour operating life at the maximum rated temperature.

Several additional types of components could be removed from the Wireless Router PCB although some are extremely small (0402 footprints), obsolete or specific to the product. The components listed in this post should have equivalents from different component manufacturers allowing salvaged parts to be used in a prototype PCB design or used for repair.