Summary

This blog presents a range of amendments for schematics or Printed Circuit Boards (PCB) with a focus on Design for Repair (DFR), which may also be referred to as Design for Service (DFS).Principle

The principle behind Design for Repair (DFR) can be described as the approach or technique of designing for repair or serviceability.

DFR Examples

There is content online which mentions DFR, such as Machine Design, Altium blog and Altium resource. Even though this content mentions DFR, examples showing changes to schematics or PCB design is exiguous. Lack of examples is unsurprising considering the uniqueness of each PCB design. Nonetheless, some examples detailed in this blog should be relevant across a variety of situations.

It should be stipulated that for commercial PCB designs the examples expressed in this blog may not apply for reasons relating to protection of intellectual property.

Schematic Net Naming

A large number of websites state the importance of naming nets and here it is reiterated. The naming of schematic nets should be effected to provide the least ambiguous information, whether the schematic detail is used during development, service or repair.

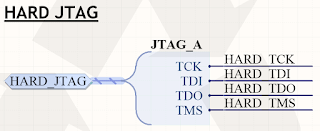

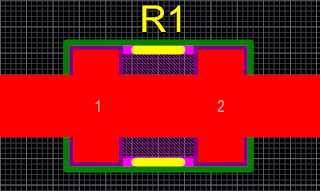

In the capture below from the Altium Connect Cube project, a common JTAG signal harness was used for soft and hard JTAG programming connections.

The two connections are differentiated in the schematic with the prefix HARD_ or SOFT_.

|

| Extract Harness Connected Cube. Courtesy Altium Ltd |

When viewing the net connections on the PCB, the type of the net is clear and understandable.

|

| PCB Extract Connected Cube. Courtesy Altium Ltd |

Schematic Component Designators

The naming of schematic components remains a debated topic. This section of the blog does not debate whether a microcontroller designator should be prefixed with "IC", "U" or "DD". Instead, designator naming should aim to use as few alphanumeric characters and be discernible on the PCB.

Certainly, there are exceptions when displaying PCB designators, especially when there are space restrictions or specific commercial equipment. For example, the Samsung S8 motherboard shown in the image below has little to no component designators.

The naming of schematic components remains a debated topic. This section of the blog does not debate whether a microcontroller designator should be prefixed with "IC", "U" or "DD". Instead, designator naming should aim to use as few alphanumeric characters and be discernible on the PCB.

Certainly, there are exceptions when displaying PCB designators, especially when there are space restrictions or specific commercial equipment. For example, the Samsung S8 motherboard shown in the image below has little to no component designators.

|

| Samsung S8 Motherboard |

It is commonplace for PCB design software to offer multi-channel part designator naming or the addition of suffixes to the component designator to identify specific schematic sheets or functions. These features are appropriate when component spacing allows for placement of longer designators.

|

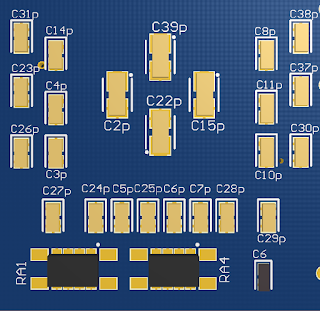

| PCB Extract Spirit Level with Designator Suffix Included. Courtesy Altium Ltd |

In space-restricted designs, where the PCB component to board area density increases above forty percent, a compact designator name allows for more valuable use of PCB real estate.

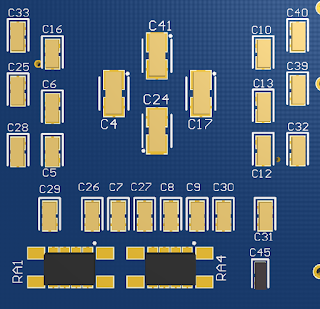

The designators shown in the above image have a suffix 'P' added to identify power supply components. While the addition of the suffix could be advantageous, this must be weighed up against the straightforward designator naming of the original PCB shown below.

Component Orientation

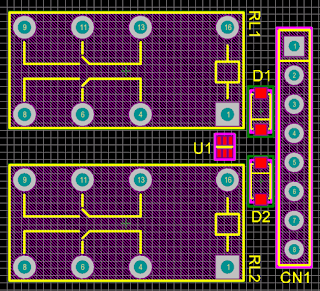

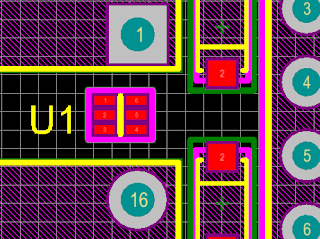

In the PCB displayed below, consider the orientation of component U1 with respect to removal through desoldering. It is most likely that the two surrounding relays would require removal to access the component.

The designators shown in the above image have a suffix 'P' added to identify power supply components. While the addition of the suffix could be advantageous, this must be weighed up against the straightforward designator naming of the original PCB shown below.

|

| PCB Extract Spirit Level with Original Designator. Courtesy Altium Ltd |

Component Orientation

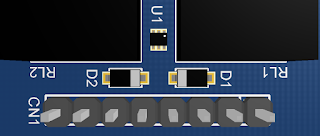

In the PCB displayed below, consider the orientation of component U1 with respect to removal through desoldering. It is most likely that the two surrounding relays would require removal to access the component.

|

| Example Component Orientation Preventing Repair |

Orientating component U1 as shown in the image below would provide an improved prospect of desoldering.

|

| Improved Component Orientation for Repair |

Optimising the orientation of a component for

repair at the time of PCB routing will commonly yield a labour-saving result.

Component Placement

Component Placement

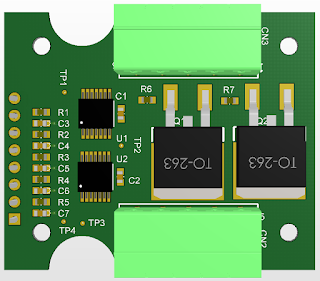

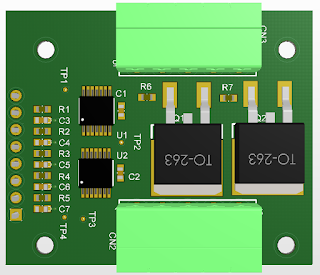

Following on from the previous section, placement of components and spacing to adjacent components can cause issues for repair when separation distances are small.

For the example PCB presented above, component U1 is shown fitted between two relays. In the event that U1 requires replacement, twin soldering irons or micro tweezers may be able to remove the component although.

Another placement option could be taken which would result in the component in a more accessible position for service equipment.

PCB Access Points

When designing a PCB to fit inside an enclosure, with a focus on maximising useable space, this can present issues when tolerances are marginal. Consider the small plug-in style PCB pictured below. No facility has been provided to remove or replace the PCB.

Another placement option could be taken which would result in the component in a more accessible position for service equipment.

|

| Example Component Placement Aiding Repair |

PCB Access Points

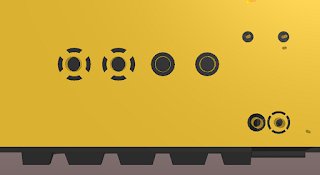

When designing a PCB to fit inside an enclosure, with a focus on maximising useable space, this can present issues when tolerances are marginal. Consider the small plug-in style PCB pictured below. No facility has been provided to remove or replace the PCB.

|

| Plug-in PCB Without Access Points for Removal |

If room on the PCB permits, the addition of access or pull points can significantly improve the ability to remove the PCB.

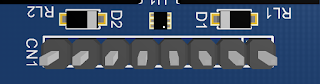

PCB Current Shunt Option

For designs containing power supplies, the unassuming current shunt can be a benefit to repair personnel.

For designs containing power supplies, the unassuming current shunt can be a benefit to repair personnel.

|

| PCB Current Shunt Option |

Designs which use a short-circuited current shunt have no component physically loaded on the PCB. The footprint could be considered a placeholder. If a need arises to isolate a supply rail or measure the current in that rail, the copper shorting the resistor is removed then the appropriate part fitted. This solution should also be considered when developing a prototype PCB.

PCB Plane Thermal Relief

External and internal copper planes often play a large role during PCB layout. During the repair process, the copper plane presents as a large heatsink for soldering and desoldering.

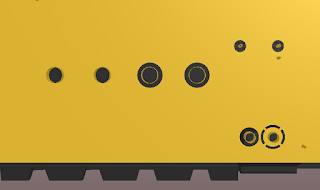

In the capture below, the two leftmost thru-hole pads are directly connected to the copper plane. While a single copper plane directly connected to the thru-hole pads can be soldered, several planes of directly connected copper tend to be a challenge.

PCB Plane Thermal Relief

External and internal copper planes often play a large role during PCB layout. During the repair process, the copper plane presents as a large heatsink for soldering and desoldering.

In the capture below, the two leftmost thru-hole pads are directly connected to the copper plane. While a single copper plane directly connected to the thru-hole pads can be soldered, several planes of directly connected copper tend to be a challenge.

|

| PCB Direct Plane Connections |

A thermal relief can be applied to the thru-hole pad. Depending on the electrical specifications of the design the characteristics of the thermal relief which include air gap, conductor width and number of conductors should be thoroughly considered.

PCB Silkscreen Pin Identification

When a new PCB component is drafted, imported from the component manufacturer or taken from an existing design, a review is always sensible.

When a new PCB component is drafted, imported from the component manufacturer or taken from an existing design, a review is always sensible.

|

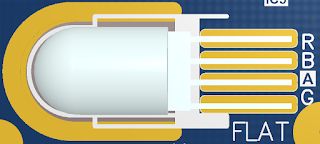

| PCB Extract DT101 PCB. Courtesy Altium Ltd |

The picture above, from an Altium example project, shows a four-pin LED with the function of each pin indicated.

PCB Silkscreen Pin Function

Additions to the PCB silkscreen, such as the voltages for the test points in the image below, can deliver technical information without the need to consult project schematics.

PCB Silkscreen Pin Function

Additions to the PCB silkscreen, such as the voltages for the test points in the image below, can deliver technical information without the need to consult project schematics.

|

| PCB Extract DB31 PCB. Courtesy Altium Ltd |

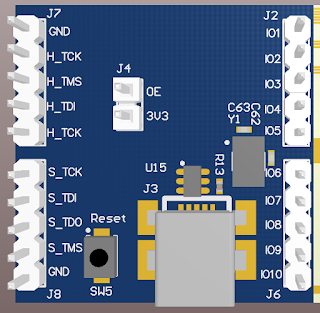

Seen below is an extract the Altium Connect Cube with the function or port detailed on the silkscreen for each pin.

|

| PCB Extract Connected Cube. Courtesy Altium Ltd |

PCB Silkscreen Assembly Extras

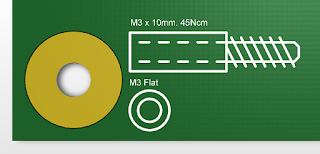

At the beginning and end of a repair commonly involves removal of mounting hardware which can include screws, washers, bolts or standoffs.

At the beginning and end of a repair commonly involves removal of mounting hardware which can include screws, washers, bolts or standoffs.

|

| PCB Showing No Mechanical Hardware Required or Assembly Information |

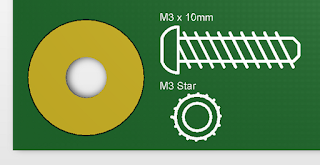

In the image below the hardware associated with the mounting hole is made evident by the PCB silk screen.

|

| PCB Showing Mechanical Hardware Required |

The next image shows the hardware required and the torque setting for the standoff.

Final Thoughts

The examples in this blog are amendments that can improve the repairability of a PCB. Design for repair is another tool in the hobbyists or Engineers arsenal, which is no different than applying sound judgement to schematic layout and PCB routing, to produce optimal results.

The examples in this blog are amendments that can improve the repairability of a PCB. Design for repair is another tool in the hobbyists or Engineers arsenal, which is no different than applying sound judgement to schematic layout and PCB routing, to produce optimal results.