While designing a prototype circuit for an LED torch it became apparent that many of the white LED controllers were surface mount leadless devices. Many of these devices have exposed pads meaning that standard soldering with an iron can be difficult.

It is possible to solder smaller devices with exposed pads by directly applying the heat beneath the device through thermal vias in the PCB, or use the oven in the household kitchen to reflow, however neither of these are ideal solutions.

Reflow Controller

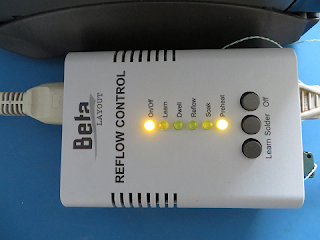

Beta Layout have for some time sold a Reflow Controller. This controller (Version2) has been reviewed with the Severin oven which Beta Layout provides however there are no reviews for ovens available locally in Australia.

|

| Beta Layout V2 Reflow Controller |

At the time of writing the Beta Layout controller sold for €119 plus shipping. There are a number of kits and Arduino style solutions on the web although for an off the shelf solution this was worth trying the controller with a locally available oven to determine suitability for home reflow soldering.

Reflow Oven

The only factor determining the oven to choose was the maximum load of the reflow controller which, for the version two model, is 1500W.

Searching the local market results in a grill from Sunbeam BT2600 with elements top and bottom. The oven retails from the GoodGuys for just under $60 AUD.

|

| Sunbeam BT2600 Oven |

It should be noted that as the controller is European made the associated mains plug and socket suit the European market. No option to order an Australian plug to female IEC plug or male IEC to Australian socket.

Oven and Reflow Controller Learn Cycle

Beta Layout's controller is for the most part plug and go. On the hardware side there is the main AC power, oven AC power and the thermocouple.

A learning cycle must be completed before the controller can be used. The thermocouple can readily be lashed to a dummy PCB (spare leaded components or enamelled copper wire) and placed in the most central position inside the oven.

|

| Sunbeam BT2600 Oven Inside |

With the door down the upper and lower heating elements are easily visible. On the front control panel the oven is switched to 240C and the timer set to OFF.

The dummy PCB is placed in the middle of the oven, door closed, power ON and the learning process is ready to start.

|

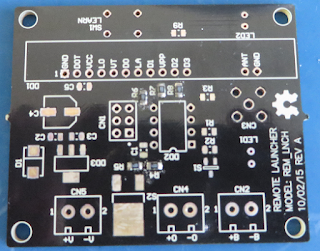

| Test PCB for Learning Cycle |

Once the learning button is pressed the oven comes to the required temperature and then the oven switches off. Subsequently it should be noted that the oven was left running standalone, in the garage, for an additional 10 min to reduce some of the VOCs. Time for a test board.

Test Board and Oven Temperature Profile

For the reflow tests the same PCB is used. A few resistor pad pairs are cleaned with flux, solder paste added and surface mount resistors applied. To apply the solder paste without a stencil, a syringe with a 0.5mm needle allows a relatively clean and controlled application of the paste.

With the PCB placed in the middle of the oven, the door is closed and the solder button is pressed on the controller. The thermocouple was left attached to the test PCB.

|

| Beta Layout Controller - Preheat Stage |

Several minutes later the reflow process has completed and the oven has cooled down sufficiently that the PCB can be checked.

|

| Test PCB after Reflow |

Inspecting the PCB, all joints to the resistors are clean and the component alignment is good - not faultless. Changes to the profile may help eliminate some bubbling on the joints.

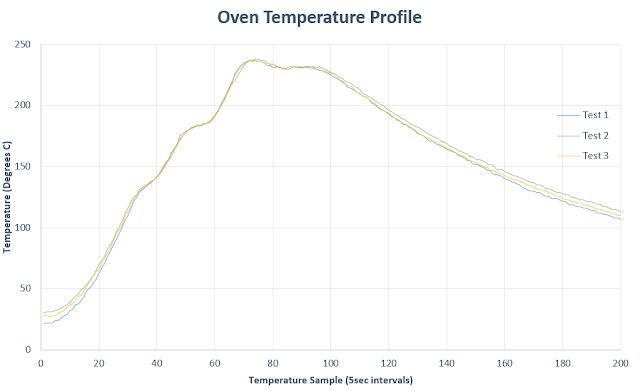

Before operating the oven again the RS232 port on the controller is connected to a laptop and a standard terminal program, TeraTerm. Using the controllers interface the automatic temperature measurements were configured to be output at 5 second intervals. A number of cycles were run across the day as the ambient temperature increased.

Below are the graphed profiles of the oven with some minor variation in the starting ambient temperature.

|

| Reflow Oven Temperature Profile |

Several subsequent tests using the oven yielded repeatable reflow results with similar sized PCB's. Reducing the oven thermostat from 240C to 210C made little difference to the results however reducing the thermostat to 190C caused issues with proper wetting and should be avoided.

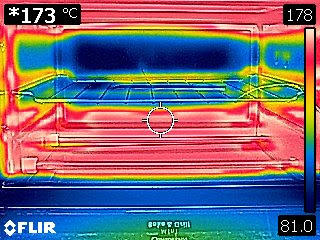

Shortly after the reflow cycle was complete the door of the oven was opened and a thermal image taken. Some of the heat has already escaped from the opening of the door.

|

| BT2600 thermal image shortly after reflow |

The temperature profile used by the controller can be manually configured through the serial interface using a terminal program.

In summary this combination of controller and oven is a valuable addition to the prototyping hardware setup which can yield excellent results for the home hobbyist.