Summary

This blog offers a solution to generate PSoC header files from

Cypress DAT files using PowerShell scripts. Available Cypress DAT files

are merged and then converted into a single header file.

There

is a thread similar to this post on the Infineon website called ‘JTAG/Silicon ID reference file’.

History

Fluctuations in global chip levels have resulted in a wider range

of microcontrollers seen by companies responsible for programming and

testing electronic hardware.

To accommodate changes in microcontrollers using a more automated process for creating software header files, the scripts mentioned in this blog were designed. These scripts are fully functional, however, not without limitations as this is an initial foray into splitting scripts with this type of file content manipulation.

The scripts were written in two parts because one script was made to run

in the Program Files directory that contains the relevant DAT files. The

second script was made to run with the merged DAT file.

Installation Requirement

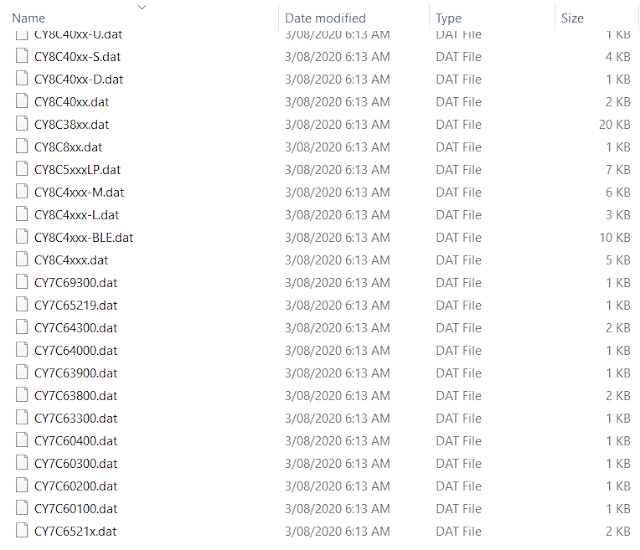

To access the DAT files, the Cypress (Infineon) PSoC Programmer

should be installed. The DAT files are located at the following location -

C:\Program Files (x86)\Cypress\Programmer\Devices

|

| Example of Cypress .DAT File Listing |

The DAT files contain various items of PSoC information. Of this, the device name and ID range are of primary interest.

As an example for PSoC device CY8C4125AZI-473, the entry from file CY8C4xxx.dat is displayed below.

2,CY8C4125AZI-473, CY8C4125AZI-473, 48, 32768, 3, 04_2B_11_93, 04_2B_12_93, v33

Whether the PSoC ID is utilised to program PSoC devices or other

information such as the size of the flash is needed for programming file

verification, the PowerShell script could easily be adapted to suit these

purposes.

Implementation

The first script called 'dat_merger.ps1' combines multiple DAT

files using the PowerShell add-content command. The script was designed to

handle all DAT files in the Cypress Programmer Devices directory however

the script will also work on a single DAT file.

Additionally, the first row in each DAT file is removed since this is

redundant. To process the file in the next script, the merged file is

saved in CSV format.

$dir = Get-Location

Write-Host "Merging Files"

$source ="$dir\*.dat"

$destination = "$dir\merge.csv"

# Remove first row and merge all files in directory

Get-ChildItem -Filter '*.dat' | ForEach-Object {

Get-Content $_ | Select -Skip 1 | Add-Content $destination

}

The second script dat_parser.ps1 removes any unwanted columns,

selects only the first column of PSoC IDs, adds the text ‘#define’,

formats the ID into a preferred value by stripping the formatting and then

saves the result as a jtag.h file.

$dir = Get-Location

Write-Host "Parsing files in $dir"

# Grab merged csv files

$source = "$dir\merge.csv"

$destination ="$dir\jtag.h"

# Strip columns, add hash define and number format for each line, strip CSV then save as header file

Import-CSV-Delim ','$source -Header a,b, c, d, e, f, g |

Select "b","g" |

ForEach-Object {$_."b" = "#define $($_."b")";$_} |

ForEach-Object {$_."g" = "0x$($_."g")";$_} |

ConvertTo-Csv -NoTypeInformation |

Select-Object -Skip 1 |

# Option for tab instead of spaces

#% { $_ -replace ‘_‘, “” -replace (‘,‘, "`t") -replace ('"', '')} |

% { $_ -replace ‘_‘, “” -replace (‘,‘, ''.padleft(10, ' ')) -replace ('"','')} |

Out-File $destination -Encoding utf8

Output

The first script would merge DAT files. Two example files were

chosen CY8C42xx-D.dat and CY8C44xx.dat.

Before Script

1,CY8C42xx-D, CY8C42xx-D, 8, 5, 128

2,CY8C4245PVI-DS402, CY8C4245PVI-DS402, 28, 32768, 3, 17_03_11_A7, v17

2,CY8C4245FNI-DS402, CY8C4245FNI-DS402, 25, 32768, 3, 17_02_11_A7, v17

2,CY8C4246PVI-DS402, CY8C4246PVI-DS402, 28, 65536, 3, 17_01_11_A7, v17

2,CY8C4246FNI-DS402, CY8C4246FNI-DS402, 25, 65536, 3, 17_00_11_A7, v17

1,CY8C44xx, CY8C44xx, 8, 5, 128

2,CY8C4A45PVI-481, CY8C4A45PVI-481, 28, 32768, 3, 1C_02_11_AC, v17

2,CY8C4A45FNI-483, CY8C4A45FNI-483, 45, 32768, 3, 1C_03_11_AC, v17

2,CY8C4A45LQI-483, CY8C4A45LQI-483, 48, 32768, 3, 1C_00_11_AC, v17

2,CY8C4A45AZI-483, CY8C4A45AZI-483, 48, 32768, 3, 1C_01_11_AC, v17

2,CY8C4A45FNQ-483, CY8C4A45FNQ-483, 45, 32768, 3, 1C_41_11_AC, v17

2,CY8C4A45LQQ-483, CY8C4A45LQQ-483, 48, 32768, 3, 1C_40_11_AC, v17

After Script

2,CY8C4245PVI-DS402, CY8C4245PVI-DS402, 28, 32768, 3, 17_03_11_A7, v17

2,CY8C4245FNI-DS402, CY8C4245FNI-DS402, 25, 32768, 3, 17_02_11_A7, v17

2,CY8C4246PVI-DS402, CY8C4246PVI-DS402, 28, 65536, 3, 17_01_11_A7, v17

2,CY8C4246FNI-DS402, CY8C4246FNI-DS402, 25, 65536, 3, 17_00_11_A7, v17

2,CY8C4A45PVI-481, CY8C4A45PVI-481, 28, 32768, 3, 1C_02_11_AC, v17

2,CY8C4A45FNI-483, CY8C4A45FNI-483, 45, 32768, 3, 1C_03_11_AC, v17

2,CY8C4A45LQI-483, CY8C4A45LQI-483, 48, 32768, 3, 1C_00_11_AC, v17

2,CY8C4A45AZI-483, CY8C4A45AZI-483, 48, 32768, 3, 1C_01_11_AC, v17

2,CY8C4A45FNQ-483, CY8C4A45FNQ-483, 45, 32768, 3, 1C_41_11_AC, v17

2,CY8C4A45LQQ-483, CY8C4A45LQQ-483, 48, 32768, 3, 1C_40_11_AC, v17

Running the second script on the

merged file output from the first script results in a new file called jtag.h as shown below.

#define CY8C4245PVI-DS402 0x170311A7

#define CY8C4245FNI-DS402 0x170211A7

#define CY8C4246PVI-DS402 0x170111A7

#define CY8C4246FNI-DS402 0x170011A7

#define CY8C4A45PVI-481 0x1C0211AC

#define CY8C4A45FNI-483 0x1C0311AC

#define CY8C4A45LQI-483 0x1C0011AC

#define CY8C4A45AZI-483 0x1C0111AC

#define CY8C4A45FNQ-483 0x1C4111AC

#define CY8C4A45LQQ-483 0x1C4011AC

One of the limitations with the current

implementation is the uneven padding between the PSoC device name and the

ID. The parser code inserts ten white spaces which may not conform with

all programming styles.

Final Thoughts

The PowerShell scripts (under GPL) have been tested on several DAT

files however the outputs should be verified as part of standard practice.

Improvements are welcomed!

Downloads

|

| dat_merger.ps1 |

|

| dat_parser.ps1 |

|

| jtag.h (Example of PSoC4, PSoC5) |