Introduction

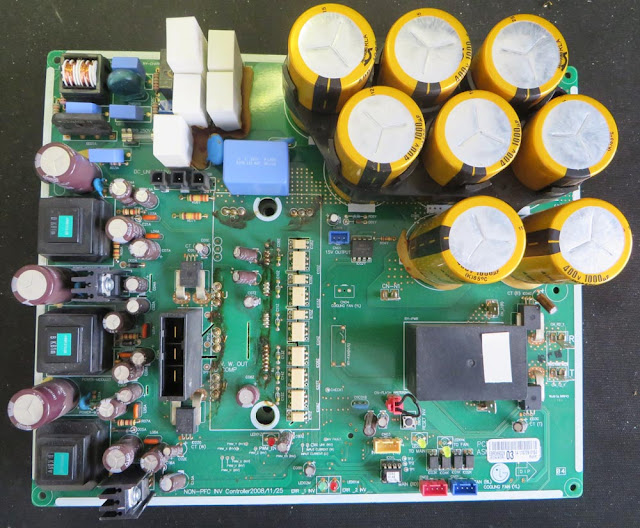

This microblog reviews the electronic components (parts) that could be salvaged from an LG air conditioner compressor inverter controller board.

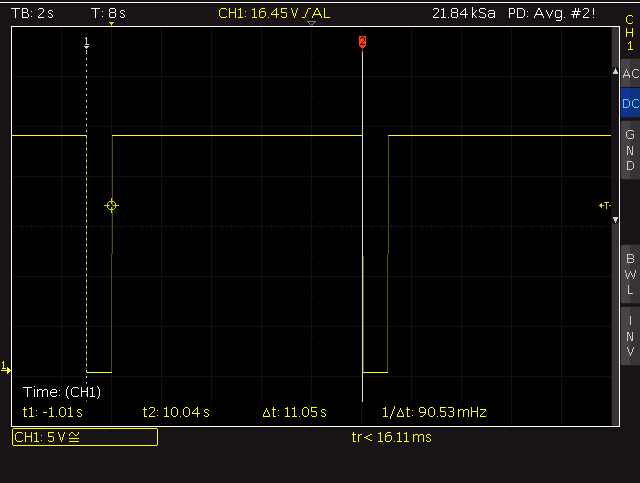

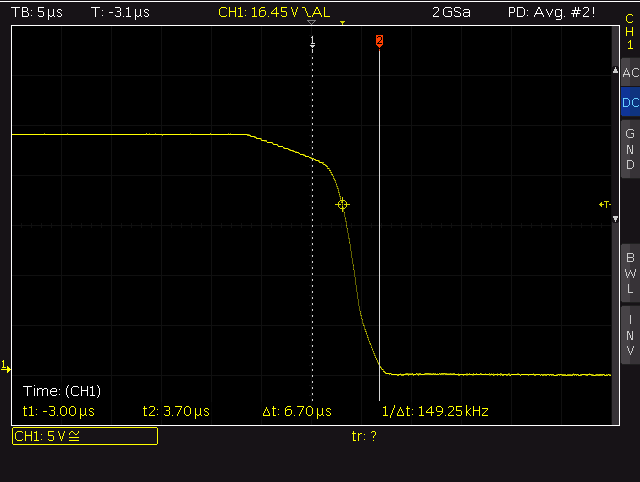

| |

| LG Control Board EBR369328 Top Side |

Summary

After being provided with the inverter controller board for spare parts, it seems relevant to detail salvageable electronic components in this blog.

Being unfamiliar with air conditioning (AC) equipment, AliExpress was used to identify the function which is listed as an LG three-phase inverter compressor (motor) control board.

It should be noted that the LG control board was supplied not working. In these instances when salvaging electronic parts, additional testing and diligence should be taken.

Salvageable Top Side Components

For the current measurement on the three-phase supply, an Allegro device capable of + 50 A, part number ACS756 was utilised. The Allegro part is listed as obsolete however this does not prevent is being used again for testing a design concept. This is one of the devices that should be tested once removed because of its use in the circuit.

|

| Allegro ACS756 |

The bulk of the electrolytic capacitors are manufactured by the Korean company, Samyoung. Some of the electrolytic through-hole capacitors associated with the mains (line) supply may be handy for spares if mains voltage projects are an area of interest.

Mains Rated Electrolytic Capacitor

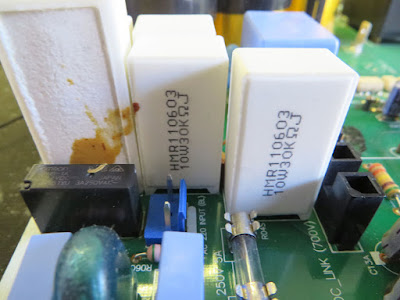

The large 10 to 20 W wire-wound ceramic resistors had no signs of overheating or physical damage. These resistors may be worth salvaging even for simple dummy loads.

|

| Wirewound Resistors |

Located near the wire-wound resistors are mains capacitors manufactured by the Korean company, Pilkor. On this LG board, those capacitors were in excellent condition and worth salvaging.

|

| Mains Capacitors |

The large vertical connector, AMP series D-5200, should be considered for anyone involved with high-current designs.

|

| AMP Connector D-5200 |

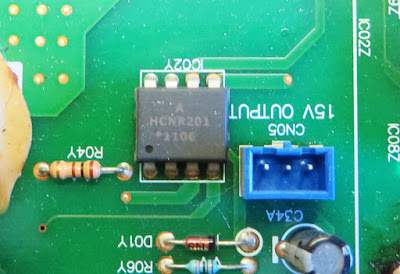

The circuit board is fitted are a few different types of optocouplers. One of the interesting parts is the HCNR201 which is a high-linearity optocoupler from Broadcom.

|

| Broadcom HCNR201 |

Other optocouplers include Toshiba TLP781, TLP559 and TLP521. All these Toshiba optocouplers are obsolete however they may serve well as spares or for repair purposes.

|

| Various Toshiba Optocouplers |

A TE relay with the part number T92S7D12-12 is fitted to the board. This relay is rated at a 12 V at 20 A and is still actively manufactured by TE.

|

| High Current TE Relay |

Contained on the board are a plethora of remaining components to consider for salvage. These include an oscillator, heatsinks, LEDs, chokes, axial resistors and unidentified components.

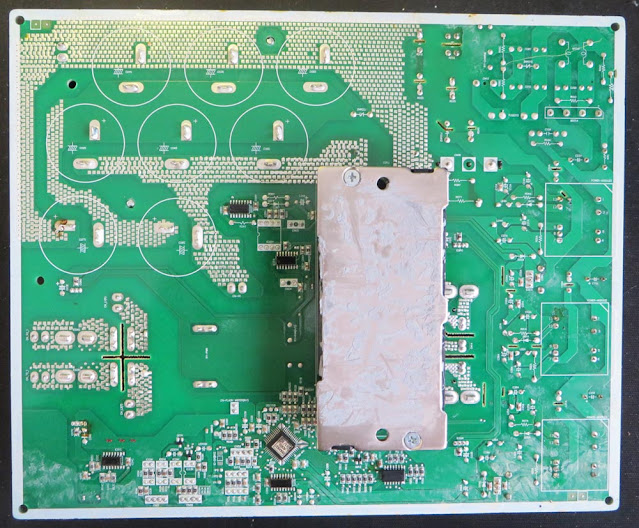

Salvageable Bottom Side Components

Fitted on the bottom side of the PCB is the motor switching module (IGBT). This device is most likely not worth salvaging.

|

| Motor Driver Module |

The semiconductors on the bottom side appear to have no identification markings or those markings have become obscured by what appears to be a protective (conformal or lacquer) coating.

|

| LG Control Board EBR369328 Bottom Side |

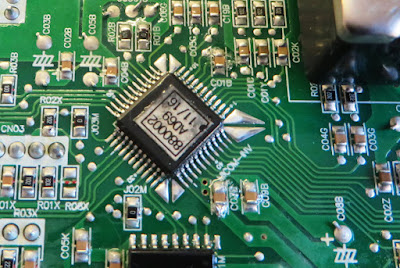

All electronic parts on the bottom side of the board are epoxy glued to the as part of the circuit board assembly process. There is little to salvage from this side of the board because of the glue although removing components is possible with the correct tools. For low-cost and high-throughput printed circuit board assemblies, soldering using wave solder in a single pass has been a common manufacturing method. This LG board employs some solder-thieving designs in the circuit board layout as pictured below.

|

| Component with Solder Thieving Pads |