Summary

Illustrated in this blog are

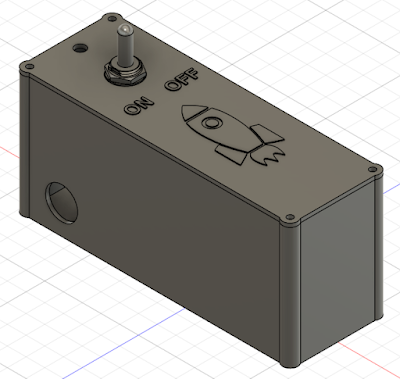

modifications to the prototype Bluetooth Model Rocket Launcher (Launcher)

carrier Circuit Board (PCB) with a view to manufacturing. This blog uses a prototype board to

highlight facets such as design simplification, reduction in dissimilar

components, part consolidation through schematic changes and reduction in the

PCB area.

|

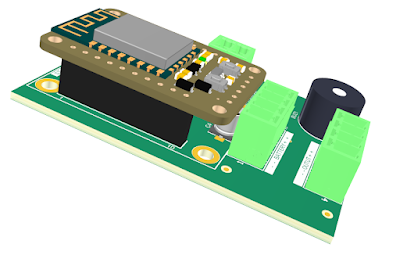

| Updated Launcher PCB 3D |

This blog does not cover cost reductions aspects

such as integrating the Cypress Bluetooth Module

into the carrier PCB or reducing the board layer geometry.

Reducing Component Count

Reducing or removing

electronic components from a design is an initial step which should be

undertaken when reviewing a board design for Production. Performing this step after

the subsequent part consolidation step may result in the repetition of one or more steps although, the review should be made on a design basis.

UHF

Receiver

The Launcher was initially designed with a UHF receiver option for backwards

compatibility. Since the Bluetooth functionality was tested in a previous blog,

the UHF receiver was removed from the design.

|

| Legacy UHF Receiver RX3302D |

|

| Legacy UHF Receiver RX3302D on Launcher PCB |

Alternate Current Sensing Option

For higher current sensing accuracy of the igniter, a TI Current Sensor INA219 was included in the design but not

used. As the accuracy was not required and current monitoring was achieved through

the ST part VN7040, the INA219 was removed.

|

| Launcher INA219 |

Feature Resistors

For the Launcher design, optional resistors were included on the board for controlling features and options in firmware however these resistors were not used. |

| Launcher Feature Resistors |

It was decided to remove half of the

resistors from the PCB. The remaining resistors were replaced with PCB pads/jumpers. These pads are bridged with solder

to enable or disable the option.

|

| Launcher Alternate Feature Selection |

Component

Consolidation

Part or component consolidation

intends to reduce the number of different parts used in the design. For a

Production environment, reducing the number of different components may assist the

board loader with aspects such as stock availability and stock holding. Some part

consolidation may physically not be practical or may lead to a detrimental change

in the performance of the circuit design. Products with multiple variants, special builds or concessions should all be singularly reviewed at

the same time. As with any design, all changes

should be reviewed and qualified.

To review parts and quantities in the Launcher design, the Bill of Materials (BOM) was reviewed.

Shown below is an extract of the BOM from the Launcher project.

|

| Launcher Bill of Materials |

Power

Supply

The switch-mode power

supply could be changed to a linear regulator. Even though a linear

regulator would be a simpler and cheaper option, the switch-mode is more

efficient and considered an improvement to the design.

Shutdown

Pin

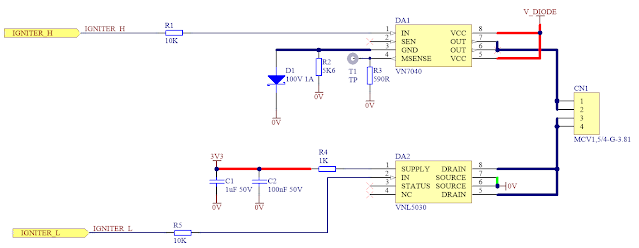

For the switch-mode controller, some components could be consolidated. The

Shutdown pin originally used a 10 k and 2.2 k resistor.

For the Rocket

Launcher, removal of the current sensor meant that few 2.2 k resistors were

used in the design.

|

Launcher Updated PSU Shutdown Circuit

|

Changing the 2.2 k resistor

on the Shutdown pin to 5.6 k consolidated the parts and raised the shutdown

voltage to a more suitable level.

Switching

Diode

The Rocket Launcher

used multiple Schottky Diodes which had forward current ratings of 1 A. One

diode’s reverse voltage was 40 V and the second 100 V. Either diode would be

more than adequate for this design.

Reviewing the characteristics, price and

availability of the diodes, the 100 V part was selected to replace the other diodes.

|

| Launcher Updated PSU Diode |

Input

Diode

The input diode was another

1 A Schottky diode with a higher reverse voltage. This was replaced with the 1

A 100 V Schottky diode. |

| Launcher Updated PSU Input Diode |

Battery

Voltage Divider

The battery voltage divider

was achieved using a 10 k and a 2.2 k resistor in the original design.

For common components, the

resistor values were changed to 5.6 k and 1 k. This change would result in adjustments

to the ADC however, this was considered trivial.

|

| Launcher Updated Voltage Divider |

Buzzer

Diode

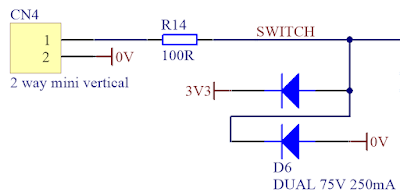

The flyback diode for

the buzzer was omitted in the original design however one of the larger Schottky

diodes was added as a footnote in the schematics. This diode was hand populated.

As the Schottky is expensive

compared to a general-purpose diode, the dual diode was used.

|

| Launcher Updated Buzzer Diode |

High

Side FET Reverse Protection

The protection components for the VN7040 consist of a diode and resistor. A 4.7 k

resistor was used as part of the circuit.

As the 4.7 k resistor was the

only part on the board, the resistor was changed to a 5.6 k.

|

| Launcher Updated High Side Protection Resistor |

FET

to PSoC Interface Resistors

There were individual 10 k resistors which connected between the PSoC and the FET

drivers.

The individual resistors were replaced with a

new part, a single 10 k resistor pack.

|

| Launcher FET Resistor Pack Update |

PSoC

Programming and Debug Resistors

The individual 100 R series resistors used between the external programming and debug connectors were

replaced with a pair of 100 R resistor packs.

|

| Launcher Debug Interface Resistor Pack Update |

|

| Launcher Programming Interface Resistor Pack Update |

Part Changes

Part changes are usually instigated for several reasons. Some of these reasons may include using the same

component type, to reduce the number of different part manufacturers, minimise components which are difficult to source or use parts already available in the current or similar

designs.

Launcher

Connector

An uncommon pluggable

connector (3-pin Canon style) was used in the original design for connection to the launcher

igniter. This connector was replaced

with the identical 4-way 5.08 mm pluggable connector used for the battery

input.

|

| Launcher Igniter Connector Update |

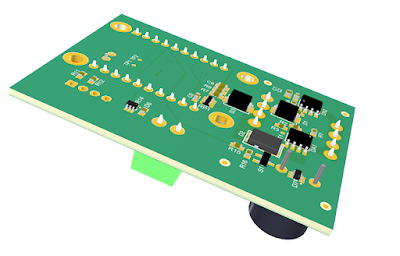

PCB Hardware

Buzzer Mounting

The buzzer was fitted

as right-angle part to the PCB on the original design. In a Production environment during board assembly (loading), hand placement (manual) soldering of the buzzer would be required.

|

| Buzzer Original Right Angle Mounting |

To simplify board loading, the

buzzer was changed from a right angle to standard thru-hole mount component on the bottom layer. As the buzzer is

provided on a reel from the manufacturer, no hand population would be required.

Top

Layer LED’s

The only surface mount components remaining on the top layer of the PCB were the

Bluetooth and Status LED's. These LED's could be considered optional parts.

|

| Launcher Original Status and Bluetooth LED's |

The LED’s were

changed to a bottom layer (rear) type which illuminates from the rear of the board. Although rear mount LED’s

are usually more expensive, the cost to manually populate the two LED’s or reflow the board a second time to maybe a more expensive option.

Mounting

Posts

To provide space between

the Launcher board and the mounting plate inside the enclosure, M3 x 50 mm zinc-plated steel posts were used. The

OLED was spaced with M2.5 x 15 mm zinc-plated steel posts.

The original M3 posts were

removed and new M2.5 x 50 mm posts were selected. Technically not an improvement

directly, however removing the M3 holes allowed a reduction in the

PCB shape.

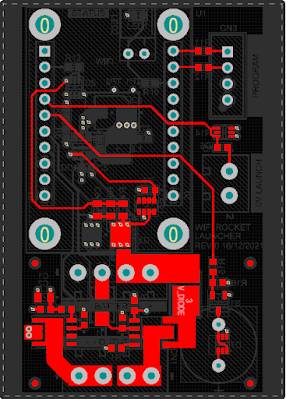

PCB

Dimensions

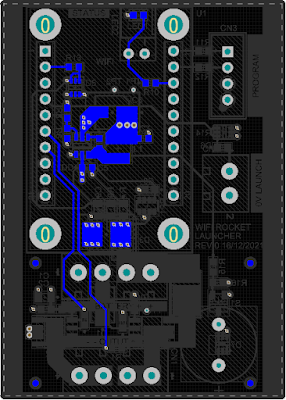

The schematic changes detailed in this post were pushed to the PCB. As shown below, some rearrangement of routed component blocks was

performed.

|

| Launcher Schematic Updates Pushed to PCB |

PCB Update

The schematic changes and updated component placement facilitated a reduction in board

dimensions. Board dimensions were changed to 82 x 69 mm.

|

| Launcher Updated PCB |

Some signal traces were

re-routed although the majority of existing signal traces were unchanged. Redundant tracks and micro planes were removed from the internal power planes of the PCB. These micro planes related to the UHF receiver.

|

| Updated Launcher PCB 3D Bottom Side |

Change Outcomes

The reduction in the PCB shape yielded a 29 % reduction in overall usage across the panel. This percentage is less if based on the actual bare PCB area.

Updating the schematic with the changes detailed in the

blog resulted in a reduction to the number of components from 68 to 53 parts

and the number of different types changed from 30 to 28.

Some new part lines in the form of resistor packs were

introduced as a result of minimising components.

Final Thoughts

This blog provided a minimalistic review of the Launcher PCB with an indication of changes to suit manufacturing.

A further review for cost reduction to suit manufacturing may mean that the Cypress Bluetooth module would be integrated into the Launcher PCB. The switch-mode power supply could be changed to a linear supply to simplify the design. The pluggable connectors on the PCB could be removed and replaced with wires because the PCB is not unplugged regularly. Additional changes could be made to the Launcher design with each change likely to impact areas outside the cost and ability to manufacture the PCB in a production environment.