Introduction

This short post details the testing of the transponder portion of the tank circuit used for the ScioSense AS3935 lightning sensor.

|

| AS3935 Block Diagram (Courtesy Sciosense B.V.) |

Sensor Board for Arduino (Educational)

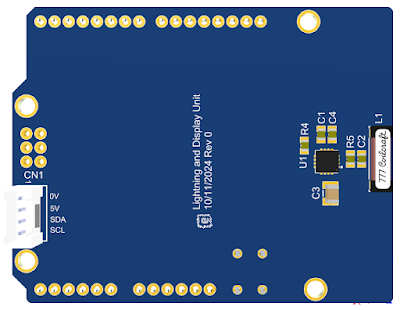

A printed circuit board (PCB) was designed for the ScioSense lightning sensor which was paired with an RGB LED (8x8) matrix as a visual output device for lightning intensity. The PCB design uses the common Arduino shield footprint to suit a controller such as the Uno or another compatible controller.

|

| 3D View of Lightning Sensor PCB |

Tank Circuit Testing

After reading comments from several forums regarding sensitivity concerns with the AS3935, I wanted to check the Q-factor of the recommended LC resonant tank circuit for lighting detection. The transponder manufacturer, Coilcraft, has an article describing testing with a Helmholtz coil however I was interested in driving the recommended tank circuit with the function generator and then measuring the resonance with a second transponder coil connected to a scope.

Coil Coupled Tank Circuit Measurements

Using the two-board setup as pictured below meant that the distance and alignment of each board (transponder coils) affected the measurements. The placement of the transponders in proximity to each other impacts the field coupling. Field coupling is explained well at this Electronics Tutorials site.

|

| Tank Circuit and Transponder Measurement Test Setup |

During the test setup, the highest coupled transponder voltage on the receiver transponder was measured using an oscilloscope. The two boards were fixed in position for consistent measurements. Measurements using this test process are not perfect because of the coupling factor between the coils (not unity) and mutual inductance can also affect measurement accuracy.

Tank Circuit Measurements

The datasheet for the AS3935 recommends a 10 k resistor in parallel with a 1 nF capacitor and the transponder coil for the tank circuit.

|

| Schematic of Tank Circuit on Test Board |

A second board with only the transponder coil fitted served as the detector through a connection to an oscilloscope.

The signal generator frequency was varied and measurements were taken using an oscilloscope. The approximate centre frequency (resonant) and the corresponding 3 dB points were determined during testing.

From the centre frequency measurements and the 3 dB points, the Q factor was calculated. Three different resistor values were tested and the table below shows a plot of the resistor values and the calculated Q factors. For the recommended tank circuit, the resonant frequency was around 494 kHz.

|

| Tank Circuit - Measurement Data |

|

| Tank Circuit - Plot of Resistor Value vs Q-Factor |

As a validation test, the FFT function on an oscilloscope was used to view the changes in the resonant frequency of the tank circuit as the the signal generator frequency was varied.

|

| Tank Circuit Measurement Validation using Field Probe |

To perform the FFT measurements, a near-field probe (Beehive Electronics) was connected to a wideband amplifier and then connected through to an oscilloscope.

Captured in the image below is the approximate resonant frequency of 488 kHz. The test board was fitted with the suggested design, a 10 k resistor, 1 nF capacitor in parallel with the transponder coil.

|

| Tank Circuit - FFT Measurement |

Final Thoughts

A standalone transponder coil was used in this post to show that a parallel RLC circuit on a different circuit board was resonating. Validation of the resonant frequency using a field probe indicated that the measurement difference between using a second transponder coil for measurement, or a field probe was less than 2 %. For accurate resonant frequency measurements, factors such as mutual inductance in the measurement device and the equipment under test should be accounted for.