Introduction

This blog provides measurement information on the maximum input frequency of the Analog Devices digital input device MAX22191. Measurements were taken for the periodic signal types square, sine and sawtooth.

| ||

| Functional Block Diagram of MAX22191 (Courtesy Analog Devices) |

Device Behaviour with Steady State Signals

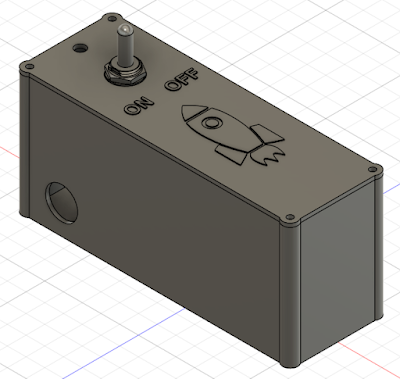

A small test board was designed for testing the MAX22191.

|

| Circuit for MAX22191 Test Board |

The circuit for the MAX22191 followed the datasheet example, consisting of a protection diode (TVS) on the input and an LED on the output. The test board was configured so that the MAX22191 was powered from an external supply.

|

| MAX22191 Development Board |

With the MAX22191 powered, the input voltage to the MAX22191 was adjusted to verify the board functionality. The supply (DC 5 V) and input voltages for MAX22191 were controlled using two supplies on a Rigol DP832 power supply.

|

| MAX22191 Setup for Input Voltage Level Tests |

Measurements with the test board showed that the upper input threshold voltage (ON) was approximately DC 9.5 V and the lower threshold voltage (OFF) was DC 7.9 V, giving a hysteresis of DC 1.6 V. These values are similar to the device datasheet values for the maximum input upper threshold voltage (ON) of DC 10 V and the lower threshold voltage (OFF) of DC 7 V.

Device Behaviour with Periodic Signals

The output of a function generator Rigol DG1022 was connected to the input of the MAX22191 to test the maximum operating frequency. For the periodic signals, the duty cycle was set and then the frequency of the function generator varied. This process was repeated for three duty cycles. The test board was powered with DC 5 V.

|

| MAX22191 Setup for Periodic Signal Tests |

The function generator output was set to High Impedance (High Z). An oscilloscope was connected to the input and output of the test board to capture the waveforms. The images in this section show the input waveform as the yellow trace and the output waveform as the blue trace.

Tests - Square

A square wave with a 10 V amplitude (loaded) was driven into the device.

|

| MAX22191 Output Capture for Square Input Signal |

For the three duty cycle settings the frequency of the function generator was increased until the output LED controlled by the MAX22191 switched OFF. The maximum frequency was measured when the output voltage from the MAX22191 dropped below 2.0 V. This was an arbitrary TTL limit for comparative purposes only.

For a 20 % duty, the LED switched OFF at 34 kHz however the output signal fell below the threshold at approximately 30 kHz.

|

| MAX22191 Output Capture for Square Input Signal 20 % Duty |

For a 50 % duty, the LED switched OFF at 180 kHz and the output signal fell below the threshold at the same frequency.

For an 80 % duty, the LED switched OFF at 260 kHz and output signals fell below the threshold at approximately 230 kHz. Some unexpected waveform behaviour was seen. This did not occur at lower frequencies such as 150 kHz. This could be an artefact of the test setup.

|

| MAX22191 Output Capture for Square Input Signal 80 % Duty |

Test - Sine

The LED switched OFF at 123 kHz and the output signal fell below the threshold at approximately 125 kHz.

|

| MAX22191 Output Capture for Sine Input Signal 50 % Duty |

Tests – Sawtooth

For a 20 % symmetry setting, the LED switched OFF at 34 kHz and the output signal fell below the threshold at the same frequency.

|

| MAX22191 Output Capture for Sawtooth Input Signal 20 % Duty |

For a 50 % symmetry, the LED was still active at 120 kHz (function generator limit) and the output waveform was still measurable.

For an 80 % symmetry, the LED was still active at 150 kHz (function generator limit) and the output waveform was still measurable.

|

| MAX22191 Output Capture for Sawtooth Input Signal 80 % Duty |

Detection Levels

The periodic signals were captured as shown in the images below to aid in visualising the voltage detection thresholds for the MAX22191.

|

| MAX22191 Input Output Levels Compared to Output for Square Input Signal |

|

| MAX22191 Input Output Levels Compared to Output for Sine Input Signal |

|

| MAX22191 Input Output Levels Compared to Output for Sawtooth Input Signal |