Introduction

In this blog, the circuit board tool Altium Designer was used to create a circuit board (PCB) coaster with an imprint on the PCB resembling a dark chocolate (cocoa) molecule.

|

| Prototype (Coffee) Cup Coasters |

Finding a Suitable Source

Before the PCB design process could be started, a suitable molecule for the PCB imprint was found online. A representation of a molecule that was more uniformly shaped was chosen to suit the shape of the PCB. Such a specific layout may not be available without manipulating the molecule’s layout.

|

| Dark Chocolate Molecule (Courtesy biobeat.nigms.nih.gov) |

The molecule in this post could have been caffeine, tea or several water molecules however for this post dark chocolate was chosen.

Creating the PCB

To begin creating the PCB artwork for the coaster in Altium, a circular arc on mechanical layer 1, with a 90 mm diameter was drawn. The 80 mm PCB diameter used in the previous coffee cup coaster was marginally too small however the overall PCB dimension should be adjusted on a project-by-project basis.

|

| Coaster PCB Shape and Size |

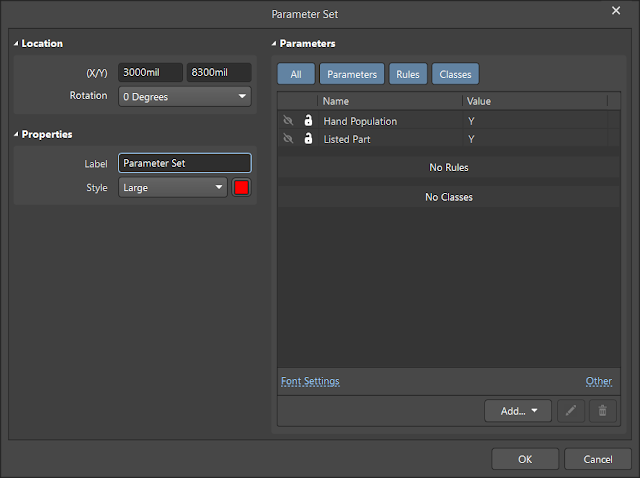

Next, the names of the individual chemicals were added as top copper layer strings. The font type sans serif was selected over serif for a modern appearance. Then the bonds between the chemical text were added to the PCB on the top overlay. Various placement and shuffling of top overlay line lengths and text were needed.

|

| Coaster Top and Silk Layers |

The next step was to duplicate the top copper layer strings. The layer properties of the copied strings were changed to the mechanical top solder layer and then placed over the top layer strings. This effectively removed the top solder mask exposing the PCB copper. Having a separate top solder layer allows for manipulation of the size and placement.

|

| Coaster Top Solder and Silk Layers |

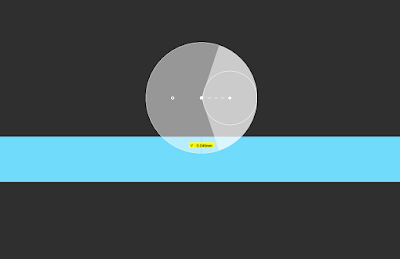

Viewing the PCB using the Altium 3D feature yields the image below for the black solder mask.

|

| Coaster in 3D |

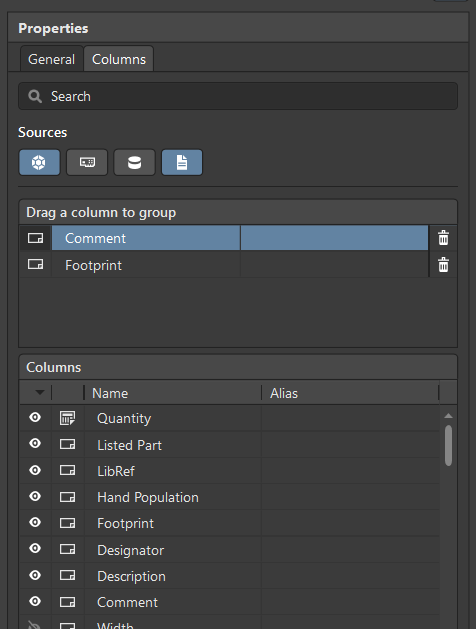

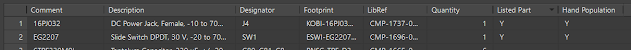

PCB Export

The requirements of the desired PCB manufacturer were checked to prepare the PCB artwork for manufacturing. As the files for the PCB manufacturer are usually in the Gerber format, the export settings for the Gerbers should be verified with the manufacturer.

Manufacturing

As noted in other blogs, the appearance and cost of the manufactured PCB may vary based on Production settings. For the PCB in this post, a black solder mask is more expensive than a green solder mask, the latter being more common.

In this post, the PCB thickness was kept at 1.6 mm since this is usually the most cost-effective thickness, a lead-free HASL (Hot Air Solder Levelled) surface finish was chosen over a lead finish and the solder mask was produced in two separate colours, green and black, to exhibit the visual difference. Lastly, the PCB manufacturer's marking was specified on the PCB bottom side overlay.

Downloads

The Gerber file can be downloaded from the link below. The files should be checked before use.

For the Gerbers the Altium export settings here were followed.

|

| Coaster Gerber Files |