Summary

This blog provides details of a novel voltage interruption tester that

demonstrates the requirements listed in the

IEC 61496-1 standard, section 4.3.2.2.

The tester was needed because certain types of electronic hardware must

be tested to the IEC 61496-1 standard and dedicated testing facilities

have had reduced access during the pandemic. The purpose of the

tester in this blog is preliminary testing which would not replace an

authorised testing facility.

Description

The interruption test hardware described in this blog was

designed for DC systems to 48 V and currents to 3 A. For design

constraints, interruption timing was considered important,

followed by access to available hardware then output voltage

regulation.

The capture below displays section 4.3.2.2

of the IEC standard which shows the timing of the three

interruption tests.

|

|

Supply Voltage Interruptions

|

Hardware Solutions

Off the shelf power supply evaluation boards such as the

Vishay SiC461

were tested initially. To control the output voltage, a

programmable resistor replaced one of the feedback elements.

By using a programmable resistor, a 10 ms pulse width was

achievable. However, the output voltage rise and fall times

were asymmetrical and several milliseconds in duration.

Alternative

solutions utilising linear regulators such as the LM317T were

analysed. The linear regulator produced very sharp output

voltage rise and fall times. The limitation of the linear

regulator was the LM317 voltage regulation and accompanying

device heat dissipation.

By utilising existing

resources, such as individual benchtop supplies, a simpler

solution was identified. It was likely that workspaces would

have access to one dual output or two single regulated

adjustable power supplies. These supplies could be used

together for the switching tests.

The hardware in

the system consisted of a microcontroller (PSoC) that

interfaced to a pair of optocouplers (4N28) in turn driving

two high-side switches (BTS50085). The output of each high-side switch was tied together with

series diodes (1N5404) to produce the output.

One design weakness using this solution was the supply to

output voltage drop. As the cumulative voltage drop of the

high-side switch and diode changed with load current, the

power supplies required adjustment to achieve the correct

test voltages.

Hardware Concept

Shown below was the original concept

proof of the hardware. The high-side

switch datasheet lists an operating

voltage to some 58 V and a current of 11

A.

|

Interruption Tester Concept Hardware

|

Circuit Overview

Control signals generation was performed by a microcontroller; any type

could perform the task as the signals are slow-moving. Two control signals

from the microcontroller drive a set of optocouplers. For this design, an

ancient pair of 4N28’s were fitted.

The transistor output of the optocouplers switched the high-side driver

inputs to 0 V. This was required as the inputs of the high-side drivers

BTS50085 must be switched to 0 V to activate their outputs.

Microcontroller

An off the shelf CY8CKIT-059 Cypress development board

implemented a PWM to drive two outputs for the optocouplers.

The onboard switch and LED acted as the user interface.

Repetitive switch presses selected a subsequent test. Flashes from the

onboard blue LED indicated the test number. No flash for off, one flash

for test one up to three flashes for test three.

For the top design in PSoC Creator, the first PWM output provided the

timing for the voltage dip. The second PWM output configuration and some

flip flops ensured that the half voltage was active before and after the

first PWM changed state. Understandably there are other ways to use the

PWM component, again this was a concept proof.

|

PSoC Creator PWM Test Setup

|

The PWM was configured as illustrated below. Settings were controlled

from within the code.

|

PWM Component Setup

|

The rise and fall times (10%, 90%) were 20 us and 90 us

respectively

with the output driving a resistive load.

|

Rise Time for Resistive Load

|

|

|

Fall Time for Resistive Load

|

Output

Waveforms

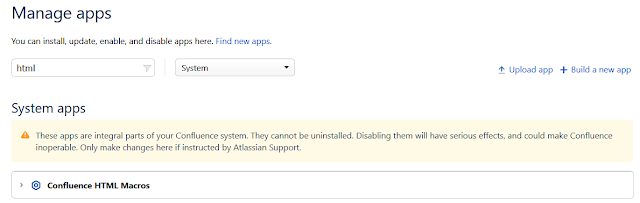

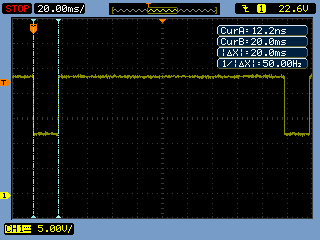

The following captures were taken when driving a resistive

load.

|

|

Interruption Test 1 with Resistive Load

|

|

Interruption Test 2 with Resistive Load

|

|

Interruption Test 3 with Resistive Load

|

The next captures were taken when driving a DC 12 V fan.

|

|

Interruption Test 1 with DC Fan

|

|

|

Interruption Test 2 with DC Fan

|

|

|

Interruption Test 3 with DC Fan

|

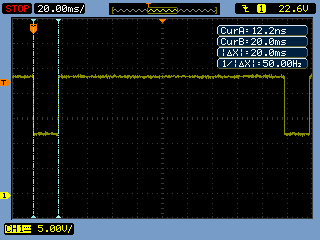

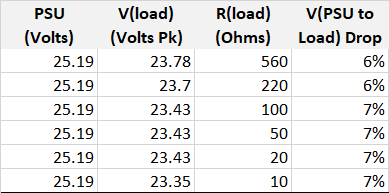

Output

Voltages

For the three interruption tests, various loads were tested and

peak voltages measured.

|

|

Interruption Test 1 with Various Resistive Loads

|

|

|

Interruption Test 2 with Various Resistive

Loads

|

|

|

|

Interruption Test 3 with Various Resistive Loads

|

The above test results show that adjustment to the power supply

voltages was required to accommodate for the system voltage drop.

PSoC

Code

Listed below is the test code for the PSoC controller.

/**

* @file main.c

* @brief Basic example of IEC61496-1 tests

* @version 0

*

* History

* Version Change Notes

* 0.0 Test code

*/

#include <project.h>

#include <stdbool.h>

/* Prototypes */

void led_flash_state(uint8 state_num);

/**

* @brief Flash LED

* @param state

*/

void led_flash_state(uint8 state_num)

{

while (state_num != 0)

{

LED_Write(true);

CyDelay(250);

LED_Write(false);

CyDelay(250);

state_num--;

}

}

/**

* Main

*/

int main()

{

CyGlobalIntEnable;

uint8 state = 0;

uint8 state_update = false;

for(;;)

{

if (SW1_Read()== false)

{

CyDelay(200); /* Some debounce */

state++;

state_update = false;

if (state == 4) /* Toggle states */

{

state = 0;

}

}

if ((state == 0) && (state_update == false))

{

PWM_Stop();

state_update = true; /* No PWM in first state */

}

if ((state == 1) && (state_update == false))

{

PWM_Stop(); /* Test 1 - 10 ms 100% dip */

PWM_WritePeriod(999u);

PWM_WriteCompare1(110u); /* Control PWM output 1 */

PWM_WriteCompare2(0u);

PWM_WriteControlRegister(PWM_CTRL_ENABLE);

PWM_Start();

led_flash_state(state);

state_update = true;

}

if ((state == 2) && (state_update == false))

{

PWM_Stop(); /* Test 2 - 20 ms 50% dip */

PWM_WritePeriod(1999u);

PWM_WriteCompare1(200u);

PWM_WriteCompare2(210u); /* Control PWM output 2 for lower voltage */

PWM_Start();

led_flash_state(state);

state_update = true;

}

if ((state == 3) && (state_update == false))

{

PWM_Stop(); /* Test 3 - 500 ms 50% dip */

PWM_WritePeriod(49999u);

PWM_WriteCompare1(5000u);

PWM_WriteCompare2(5010u); /* Control PWM output 2 for lower voltage */

led_flash_state(state);

state_update = true;

}

}

}

/* End */

Summary

For concept proof, the tests using high-side switches controlled by a microcontroller verified specific requirements detailed in the IEC 61496-1 standard. During tests, the input to output voltage drop was less than 10 %. Compensation for voltage drop was achieved by adjusting power supply voltages.

Depending on design requirements, a different microcontroller, high-side switches with a lower operating voltage, or alternative components could be selected. If isolation from the switched output voltage was not a consideration, the optocouplers could be omitted.

With access to testing facilities being limited, having the hardware to provide preliminary on bench verification can be a consolation.

Downloads

The PSoC Creator 4.4 project and schematic from the Top Design are available for download.