This blog details the build process of an enclosure for isolation transformer using a medical grade toroidal transformer.

Medical Grade Transformer

Transformer Selection

A transformer manufactured by Triad Magnetics (China) was selected for mains 240VAC. The Triad Magnetics parts VPM240-670 is rated at 160VA which is usually ample for fault finding equipment or powering small pieces of test equipment.

The transformer features a number of winding options for 110VAC or 240VAC.

For this design the primary and secondary will be configured for 240VAC operation.

Hardware Selection

In addition to the transformer are a number of key components such as the enclosure, IEC connectors, fuses and switch. A standard plastic enclosure was chosen to house the transformer as the expected operational time was low. For long operating periods a vented case would be used.

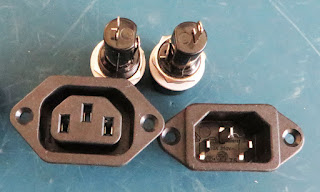

Shown below are the fuse holders and IEC inlet outlet chassis mount connectors.

Hardware Mounting

The hardware required for the design was measured and the mark-ups were made on opposite ends of the enclosure.

Standalone 3AG fuse holders were chosen over IEC connectors with integrated M205 type fuses however either is suitable for this design.

Mounting for a double pole rocker switch and the transformer were added.

Hardware Dry Fit

Each piece of hardware was mounted to ensure that fitting was suitable and clearances were sufficient.

Enclosure Wiring

Salvaged mains 300V AC rated cable was used to wire between the IEC connectors and the fuses.

All mains connections were soldered and the mains wire was passed through the eyelet as shown below.

All connections were insulated with heat shrink tube.

Medical Grade Transformer

There are significant benefits in using a medical grade toroidal transformer over a standard type. These include multiple layers of winding insulation, reduced leakage currents and certain types of internal transformer failures can lead to a winding short to mains earth resulting in protected equipment and operators. Such a short to mains earth is achieved because a medical transformer contains a dedicated mains earth connection. Medical transformers are usually made to a international standard such as IEC / UL 60601-1.

Transformer Selection

A transformer manufactured by Triad Magnetics (China) was selected for mains 240VAC. The Triad Magnetics parts VPM240-670 is rated at 160VA which is usually ample for fault finding equipment or powering small pieces of test equipment.

|

| Triad Magnetics VPM240-670 |

|

| Triad Magnetics VPM240-670 Side View |

Hardware Selection

In addition to the transformer are a number of key components such as the enclosure, IEC connectors, fuses and switch. A standard plastic enclosure was chosen to house the transformer as the expected operational time was low. For long operating periods a vented case would be used.

|

| Enclosure |

|

| Associated Isolation Transformer Hardware |

The hardware required for the design was measured and the mark-ups were made on opposite ends of the enclosure.

|

| Inlet and Fuse holder Mounting |

|

| Outlet and Fuse holder Mounting |

|

| Transformer Mounting |

Hardware Dry Fit

Each piece of hardware was mounted to ensure that fitting was suitable and clearances were sufficient.

|

| Hardware Dry Run |

Salvaged mains 300V AC rated cable was used to wire between the IEC connectors and the fuses.

|

| 300V Mains Cables |

|

| IEC Mains Cable Connection |

|

| Fuse with Heat shrink |

The image below shows the rather snug wiring prior to testing. Additionally, while tightening the IEC fixings the case cracked meaning the entire case would need to be replaced after some initial testing.

Regulation Testing

The transformer was wired for 240V AC on the primary and secondary.

Using the wiring configuration for 240VAC, regulation measurements were performed to approximately 130VA using a Fluke 325.

|

| Wired Isolation Transformer |

The transformer was wired for 240V AC on the primary and secondary.

|

| Transformer Input and Output Options |

Shown in the image below are the transformer windings as detailed on the Triad Magnetics datasheet.

|

| Transformer Windings |

|

| Triad Magnetics Transformer Regulation |

With a load of 130VA the transformer regulation was approaching the 7.2% maximum quoted regulation of the transformer at full load.

Comments

With very small loads the transformer secondary voltage is almost 10% higher than the primary voltage. For voltage sensitive equipment this differential may be a limiting factor although for standard bench testing this transformer is more than suitable.

Comments

With very small loads the transformer secondary voltage is almost 10% higher than the primary voltage. For voltage sensitive equipment this differential may be a limiting factor although for standard bench testing this transformer is more than suitable.