Introduction

This blog details the fitting of the drill press controller's input circuitry and simple validation testing of the updated input circuitry.

Input Device Validation

In the earlier drill press post describing updates to the controller, the input circuitry (24 V) was changed from using discrete components to the PLC (Programmable Logic Controller) input device, the MAX22191, from Analog Devices.

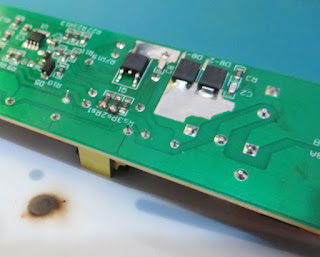

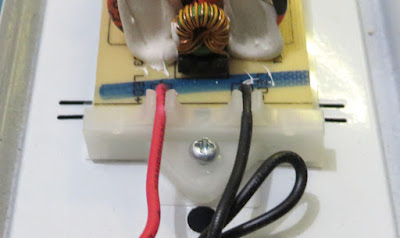

The PLC input devices were soldered to the prototype board along with the input connector. It should be noted that the footprint for the MAX22191 on the board was found to be incorrect; however, testing was still possible.

|

Controller and Sensor Test Setup |

The output of a power supply was connected to one of the PLC inputs, and the ON/OFF thresholds were measured by varying the voltage to the MAX22191 in 100 mV increments. The approximate threshold voltages were measured for an ON at 8.9 V, and the OFF voltage was 7.8 V. These voltages fall within the range specified by the ‘IN Voltage Upper Threshold’ and ‘IN Voltage Lower Threshold’ as stated in the MAX22191 datasheet.

Connecting a Proximity Sensor

The drill press controller utilises a proximity sensor to detect the spindle speed, with the output signal from the sensor resembling a square wave. The proximity sensor was connected to one of the MAX22191 inputs for testing. The output of the MAX22191 connects directly to the microcontroller (PSoC), so a pass-through connection was made in the PSoC for testing purposes. Using the PSoC fabric, the sensor input was routed to a test pin, which had a test pad.

|

| PSoC Creator Spindle Pass-Through Connection |

Shown below is a pulse from a magnetic sensor and the PSoC test pin, as measured by an oscilloscope. Oscilloscope channel 1 represents the input to the MAX22191, and channel 2 represents the PSoC test pin output. Upon reviewing the input and output signals, there is little difference in the timing of the signals, which is ideal for ensuring no change to the spindle

speed measurement.

|

| Sensor Test Pulse Measurement |

As an additional check, the delay from the proximity sensor to the rising edge of the output signal was also captured, as shown in the image below.

|

| Sensor Test Pulse Rising Edge Measurement |

In the next post, the final check will be performed on the debug channel, which is a TTL signal, and the circuit board will be updated with any changes.