Summary

This blog briefly describes the new processor used on the EPEVER WiFi

2.4 GHz to RJ45 Adaptor (Ver 4.0) hardware. The command line interface (CLI)

provided by the WiFi adaptor is also described. This interface was used to confirm the default IP

address of the unit in AP (Access Point) mode was 192.168.169.2

|

|

EPEVER WiFi RS485 Adaptor (V4) |

WiFi Hardware

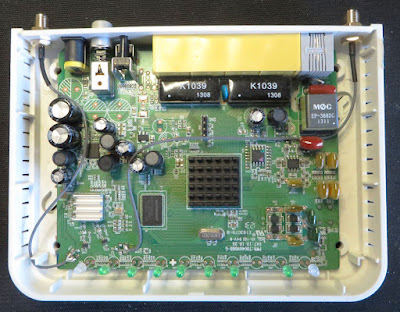

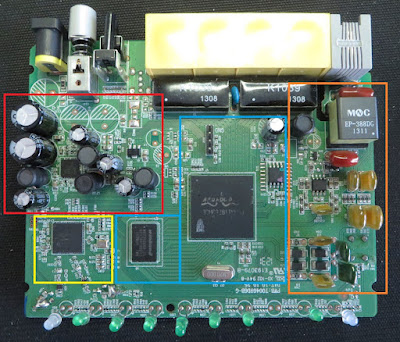

The latest version of the EPEVER WiFi Adaptor hardware with the black plastic enclosure uses a Winner Micro W600-B800 System on Chip (Soc). Also contained on the circuit board is the serial flash required by the SoC, RS485 driver, switch mode supply and associated passive components.

Interface to SoC

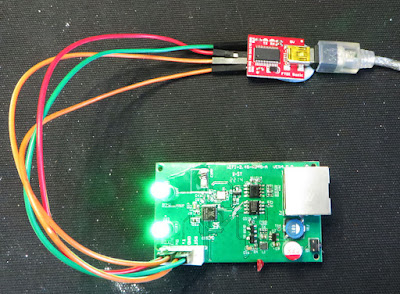

A SparkFun FTDI Basic adaptor was configured for 3.3 V and then connected to the 5-way header on the WiFi circuit board. The other side of the USB to TTL converter was connected to a PC.

|

|

EPEVER to USB Converter |

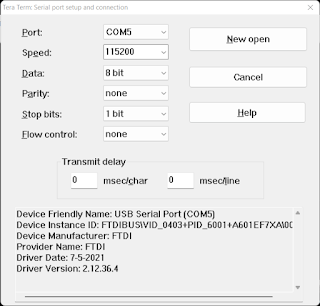

After reviewing the SoC datasheet, serial port settings of 115200, 8, N, 1

were used with a terminal program. The capture below shows the port settings for Tera Term.

|

|

Tera Term Communications Settings for EPEVER Debug |

WiFi Adaptor Output Log

The output log from the WiFi adaptor SoC shows that the

RT-Thread RTOS is

used. There is a plethora of reading material on the RT-Thread

website including the tools

required for interfacing with the SoC. These software packages were not

verified in this post.

In the log shown below, the default IP address of the WiFi adaptor is listed as 192.168.169.2 with a port of 65010 for communincations to the RS485 port.

[SFUD]Warning: Read SFDP parameter header information failed. The norflash is not support JEDEC SFDP.

[SFUD]Warning: This flash device is not found or not support.

[SFUD]Warning: Read SFDP parameter header information failed. The norflash is not support JEDEC SFDP.

[SFUD]Warning: This flash device is not found or not support.

[SFUD]Error: norflash flash device is initialize fail.

[I/FAL] RT-Thread Flash Abstraction Layer (V0.4.0) initialize success.

[E/OTA] (ota_main:41) download partition is not exist, please check your configuration!

[D/OTA] (ota_main:105) jump to APP!

redirect_addr:8010100, stk_addr:20005888, len:851968

\ | /

- RT - Thread Operating System

/ | \ 4.0.2 build Feb 25 2022

2006 - 2019 Copyright by rt-thread team

lwIP-2.0.2 initialized!

ERROR: SPI device fl_spi not found!

[I/sal.skt] Socket Abstraction Layer initialize success.

[D/FAL] (fal_flash_init:61) Flash device |w60x_onchip | addr: 0x08000000 | len: 0x00100000 | blk_size: 0x00001000 |initialized finish.

ERROR: Flash device w25q128 not found!

[D/FAL] (fal_flash_init:61) Flash device |norflash | addr: 0x00000000 | len: 0x00000000 | blk_size: 0x00000000 |initialized finish.

[D/FAL] (fal_partition_init:176) Find the partition table on 'w60x_onchip' offse t @0x0000ff88.

[I/FAL] ==================== FAL partition table ====================

[I/FAL] | name | flash_dev | offset | length |

[I/FAL] -------------------------------------------------------------

[I/FAL] | app | w60x_onchip | 0x00010100 | 0x000d0000 |

[I/FAL] | easyflash | w60x_onchip | 0x000e0100 | 0x00004000 |

[I/FAL] | filesystem | w60x_onchip | 0x000e4100 | 0x00019000 |

[I/FAL] =============================================================

[I/FAL] RT-Thread Flash Abstraction Layer (V0.3.0) initialize success.

[Flash] (packages\EasyFlash-v3.3.0\src\ef_env.c:152) ENV start address is 0x00000000, size is 8192 bytes.

[Flash] (packages\EasyFlash-v3.3.0\src\ef_env.c:821) Calculate ENV CRC32 number is 0xD6114A34.

[Flash] (packages\EasyFlash-v3.3.0\src\ef_env.c:833) Verify ENV CRC32 result is OK.

[Flash] (packages\EasyFlash-v3.3.0\src\ef_env.c:821) Calculate ENV CRC32 number is 0x78CA81B2.

[Flash] (packages\EasyFlash-v3.3.0\src\ef_env.c:833) Verify ENV CRC32 result is OK.

[Flash] EasyFlash V3.3.0 is initialize success.

[Flash] You can get the latest version on https://github.com/armink/EasyFlash .

<--------------------software: GT100WS142W600T------------------>

tls_fls_init() return 2

init MyFile obj is success.

enter InitHnjdClass() success.

ql_dev_init()=0

<-- lt_sock_para_1() APP_NV_SYS=,ret=0. ID=00065689.MAC=202205111459122 -->

<--init0 hnjd paraments success loraSize=0-->

Hnjd_GetImei(), imei:202205111459122;

<--init hnjd paraments success loraSize=0-->

init gpio class success.

RT-Thread create eventUart2Recv successful

init serial class success.

init logs class success.

Hnjd_GetImei(), imei:202205111459122;

SecCount=-1,SendCount=0

SecCount=-1,SendCount=0

COM<-- 89 D2 D4 D2 D2 D4 CF D3 D3 D3 D0 CF CB D3 D2 D2 00 D4 D4 D4 D4 D4 D4 23 1D A8 88

msh />gpio task running......

serial task2 running......

COM--> 89 D2 D4 D2 D2 D4 CF D3 D3 D3 D0 CF CB D3 D2 D2 00 D2 D4 D4 CC D4 D3 23 1D 9D 88

TEA success.

init system success.

[D/DFS] enter AP mode

[I/WLAN.dev] wlan init success

[I/WLAN.lwip] eth device init ok name:w0

[I/WLAN.mgnt] start ap successs!

[D/DFS] rt_wlan_start_ap(HN_65689,12345678) return RT_EOK.

[D/DFS] main() enter UserMain()

enter InitSockClass()

exit InitSockClass()

[DHCP] dhcpd_start: w0

[DHCP] ip_start: [192.168.169.2]

[DHCP] ip_start: [192.168.169.254]

enter lt_RtuTask()

local ip:0.0.0.0 port:65010

TCPServer Waiting for client on port 65010...

RT-Thread create eventSockSendRecv successful

serial init success. baud=115200,parity=8N1

Should anyone want to delve further, typing help in Tera Term indicated the menus displayed below.

setenv - Set an envrionment variable.

printenv - Print all envrionment variables.

saveenv - Save all envrionment variables to flash.

getvalue - Get an envrionment variable by name.

resetenv - Reset all envrionment variable to default.

fal - FAL (Flash Abstraction Layer) operate.

ntp_sync - Update time by NTP(Network Time Protocol): ntp_sync [host_name]

list_fd - list file descriptor

date - get date and time or set [year month day hour min sec]

sf - SPI Flash operate.

wifi - wifi command.

version - show RT-Thread version information

list_thread - list thread

list_sem - list semaphore in system

list_event - list event in system

list_mutex - list mutex in system

list_mailbox - list mail box in system

list_msgqueue - list message queue in system

list_memheap - list memory heap in system

list_mempool - list memory pool in system

list_timer - list timer in system

list_device - list device in system

help - RT-Thread shell help.

ls - List information about the FILEs.

cp - Copy SOURCE to DEST.

mv - Rename SOURCE to DEST.

cat - Concatenate FILE(s)

rm - Remove(unlink) the FILE(s).

cd - Change the shell working directory.

pwd - Print the name of the current working directory.

mkdir - Create the DIRECTORY.

mkfs - format disk with file system

df - disk free

echo - echo string to file

ps - List threads in the system.

time - Execute command with time.

free - Show the memory usage in the system.

ifconfig - list the information of all network interfaces

ping - ping network host

dns - list and set the information of dns

netstat - list the information of TCP / IP

smartconfig_demo - smartconfig demo

reboot - Reboot System

msh />

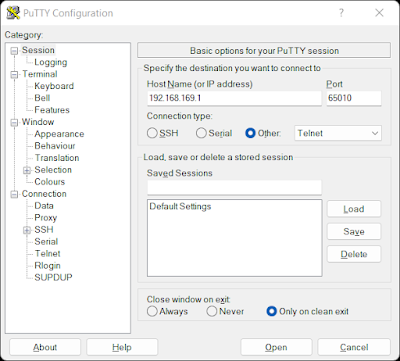

To verify the WiFi adaptor was operating, a computer with a suitably

configured WiFi IP address was tested with Putty.

|

| Putty Communications Settings for EPEVER Testing |

With the Tera Term debug connection to the WiFi adaptor active, a connection using Putty was established. The packet highlighted in the capture below was received by the WiFi adaptor and appeared consistent with a connection from Putty.

[I/WLAN.mgnt] sta associated mac:bc:09:1b:eb:06:3b

I got a connection from (192.168.169.2 , 51147)

COM<-- FF FB 1F FF FB 20 FF FB 18 FF FB 27 FF FD 01 FF FB 03 FF FD 03

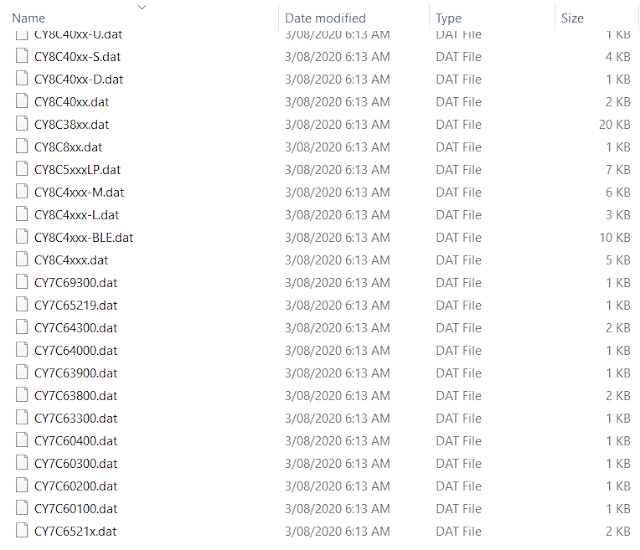

Final Thoughts

The test mentioned in this blog using Putty confirmed that the EPEVER WiFi adaptor worked. A separate test with an Android phone (point-to-point), not mentioned in this blog, did not show the same behaviour.

The access point connection with point-to-point or cloud is not a preferred solution. The WiFi adaptor firmware could likely be reconfigured to operate in station

mode. Whether EPEVER is required to rebuild the source, or this option is already provided in the CLI remains to be determined. Station mode is supported by RT-Thread as indicated in the capture below.

[*]

Using Wi-Fi

framework

/* Using Wi-Fi framework */

(wlan0) The WiFi device name for station /*

The default name for station */

(wlan1) The WiFi device name for

ap /* The default name for ap */

(lwip)

Default transport protocol /*

Default protocol */

(10000) Set scan timeout

time(ms) /* Scan timeout time

*/

(10000) Set connect timeout time(ms) /*

Connect timeout time */

(32) SSID name maximum

length /*

Maximum length of SSID name */

(32) Maximum password

length /*

Maximum length of password */

[*] Automatic sorting of scan

results /* Automatic sorting of scan results */

(3)

Maximum number of WiFi information automatically saved /* Maximum number of

WiFi information automatically saved */

(wlan_job) WiFi work queue

thread name /* WiFi work queue thread name */

(2048) wifi

work queue thread size /* wifi work

queue thread size */

(22) WiFi work queue thread

priority /* WiFi work queue thread priority */

(2)

Maximum number of driver events /* Maximum number of

driver events in dev layer */

[ ] Forced use of PBUF

transmission /* Forced use of PBUF transmission */

[

] Enable WLAN Debugging Options /*

Enable WLAN Debugging Options */